- Today is:

Breaking news

News

Stay informed. Our latest news and announcements.

Share Your News with Our Community

Are you a brand, supplier, or professional? Submit your news and get featured on PackagingConnections.

Sparxell, a University of Cambridge spin-out and innovator of bioinspired colour technology, has raised €4.2 million ($5 million) in pre-Series A…

Amazon works with IIT Roorkee to convert agricultural waste into biodegradable paper mailers, addressing stubble burning problems while creating…

Mondelēz International, Inc. today opened applications for the 2026 class of CoLab Tech, the company’s global R&D tech accelerator program. The…

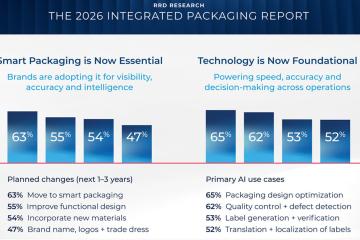

RRD has released its 2026 Integrated Packaging Report, revealing a substantial disconnect between industry ambition and real-world adoption…

Mindbodygreen has recalled more than 148,000 bottles of its Ultimate Multivitamin+ dietary supplement due to packaging that fails to meet federal…

goplasticpallets.com, the responsible plastic pallet company, has further strengthened the portfolio of products it supplies to the UK waste…

The drive to improve sustainability levels in beauty packaging continues with department store Selfridges now partnering with MyGroup to launch a…

A new cardboard and box packaging production site has opened in the Sumgayit Industrial Park, Azerbaijan.Managed by “Baku Cardboard and Box Factory…

At CES 2026, PepsiCo (NASDAQ: PEP) announced a multi-year, industry-first collaboration with Siemens and NVIDIA to digitally transform its…

Alter Eco produces chocolate using carefully selected organic cacao, sourced through fair and transparent supply chains. Grown by small scale farms…

Pagination

- First page

- Previous page

- …

- 5

- 6

- 7

- 8

- 9

- …

- Next page

- Last page