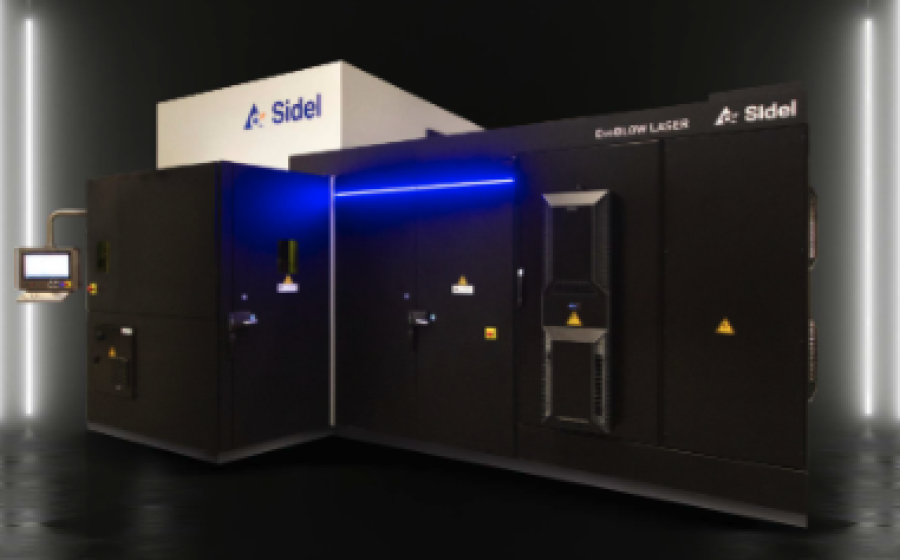

At drinktec 2025 (Hall A6, Booth 361), Sidel is set to redefine performance and sustainability in beverage packaging with the global launch of EvoBLOW Laser — the world’s first industrialised laser-powered PET blowing solution. This breakthrough marks a transformative step forward in lightweighting, efficiency, and quality for PET and rPET packaging.

“Sidel has led the way in blowing technology for over 45 years,” said Pietro Cassani, President and CEO of Sidel. “In 1980, our pioneering PET blower revolutionised the industry. Now, with EvoBLOW Laser, we’re reshaping it once again — setting new standards for line efficiency and unlocking unprecedented lightweighting opportunities.”

A New Era for Packaging Technology

For decades, halogen heating technology has dominated PET packaging. While it has evolved, its inherent limitations have remained. With EvoBLOW Laser, Sidel introduces a viable, future-ready alternative that addresses these constraints head-on — offering producers a pathway to reduce costs, enhance sustainability, and boost operational agility.

Precision-Driven Lightweighting — Stronger, Yet Lighter

Laser technology delivers unmatched precision, enabling both lighter and stronger bottles — a long-standing paradox in packaging design.

Unlike halogen systems that heat preforms in broad zones, EvoBLOW Laser uses up to 36 ultra-precise heating lines, compared to just eight in conventional setups. This precision gives operators granular control over material distribution, enabling record-breaking weight reduction without compromising strength.

Sidel’s innovation introduces invisible “power rings” — subtle reinforcement zones that replace traditional ribs. These enhance strength while preserving design freedom and aesthetics, even allowing lightweighting near the bottle neck — a previously unreachable area.

Perfect from the First Bottle, Every Time

Environmental conditions can affect halogen heating, requiring constant manual adjustments. EvoBLOW Laser eliminates this variability.

The laser system is environment-independent, maintaining a stable and consistent heating profile regardless of temperature or humidity. With just one process setting per heating line, the system ensures that every preform — from the first to the last — achieves identical quality.

Unmatched Line Efficiency and Flexibility

EvoBLOW Laser sets new benchmarks in line efficiency. Its instant cold-start capability eliminates warm-up and cool-down times, reducing downtime and energy waste. No standby mode is needed, allowing for immediate restart after production stops.

Additionally, live speed modulation allows the blower to dynamically adjust its pace in real-time to accommodate line conditions, improving throughput stability.

The system also supports a broader range of bottle formats and shapes from the same preform, streamlining operations and logistics.

Safety, Ease, and Operational Peace of Mind

Operators benefit from stress-free handling and maintenance. The cold-oven design eliminates burn risks, while instant access to components allows for quicker interventions.

The intuitive “touch and shape” interface simplifies operation, and the system’s maintenance-free laser diodes and absence of fans or filters reduce servicing time and costs.

Driving Sustainability and rPET Adoption

EvoBLOW Laser supports the industry’s shift toward higher rPET content by accommodating greater material variability. Its precision heating enables faster processing and optimal stretch ratios, reducing preform waste and energy use.

The compact oven design further reduces the equipment’s carbon footprint, contributing to more sustainable production lines.

Proven in Partnership: Refresco Leads the Way

The technology has already undergone rigorous field testing with Refresco, the world’s largest independent beverage solutions provider.

“After 45 years of halogen technology, we are entering a new era,” said Coert Michielsen, Chief Supply Chain Officer at Refresco. “Laser oven technology will become the new standard.”

Shaping the Future of PET Blowing

With EvoBLOW Laser, Sidel once again redefines what’s possible in PET and rPET packaging.

Combining precision engineering, operational simplicity, and sustainability, this innovation represents a decisive leap forward — one that positions Sidel and its partners at the forefront of the next generation of packaging technology.