Activity

-

-

Tecnoferrari group lands in the united s...

After a long research and a detailed analysis, Tennessee, a strategic hub for the US industry, was identified as the

-

Gcube ecobalance™: sustainable ibc bot...

The inner layer of the sustainable bottle is 100 percent virgin high density polyethylene (HDPE), while the external

-

Greif, inc. announces agreement to sell ...

Pete Watson, Greif’s President and Chief Executive Officer, commented, “We are pleased to enter into this agreement w

-

Working at aptar: celebrating thai tradi...

Last month the Aptar Chonburi team came together to pay respect and food offering to the Brahma shrines and spiritual

-

Study of plastic packaging waste helps t...

CEFLEX and partners PCEP, Petcore Europe, Styrenics Circular Solutions and MORE Recycling team up to understand the reality of today’s collected household packaging waste – a vital step forward towards a circular economy for packaging materials.

Hailed as Europe’s first in-depth analysis of its kind, the resulting data aims to reveal the amounts and types of post-consumer flexible and rigid plastic packaging, in the two main waste streams in which it is collected. Sharing the findings of the study is expected to define and deliver a circular economy for all packaging materials.

The amount of how much packaging is placed on the market is only half of the story. So, a better analysis of packaging used by consumers and collected through waste streams is needed. This will help to define and accelerate development of the required infrastructure, systems and end market applications, which are required to enable progress in delivering a circular economy.

The study has been initiated by CEFLEX (Circular Economy for Flexible Packaging) in collaboration with the other key partners in the plastic packaging value chain – Polyolefin Circular Economy Platform (PCEP), Petcore Europe, Styrenics Circular Solutions and MORE Recycling. It covers all types of consumer packaging found in today’s households – everything from wrappers, bags and pouches to bottles, trays and tubes - across key European markets.

The analysis is being conducted by leading environmental consultancy Resource Futures. Researchers are manually sorting, identifying and weighing representative samples, then attributing the collected waste packaging to nearly 200 categories. In addition, the team maps where packaging appears in the recyclables or residual waste streams and use Near Infrared technology to give a detailed breakdown of polymer types.

“This is vital information about how material flows through the system today – and what collection, sorting and recycling solutions are required to deliver a circular economy for flexible packaging and other packaging materials,” said Graham Houlder, CEFLEX Project Coordinator.

“Initial results from the first country studied show significant quantities of recyclable materials remaining in the mixed waste stream, suggesting the need to improve the capture and re-use of these materials,” he added.

These types of insights can help Extended Producer Responsibility (EPR) and other schemes to pinpoint what is needed to go ‘circular’ and fine tune eco-modulation. This will encourage the design of flexible packaging which boosts the amount of recycled content in a variety of end market applications, according to CEFLEX.

Venetia Spencer, Secretary General, PCEP, commented, “I am very excited by this project, which already in the early stages has brought enormous insight. Accurate understanding of the polyolefins collected via recycling and residual household waste streams, will play an important role in delivering PCEP’s commitment to enhance collection and sorting of polyolefins.”

Capture and capitalise on real-world material flows

Initial results of the first country analysis (UK) showed:

> 4595kg of material was manually sorted and categorised at two sites; of which 3240kg was residual waste and 1355kg was separately collected recyclables.

> 66.5% of flexible packaging found in the residual waste samples was categorised as recycle ready mono-material – this includes mono-PE, mono-PP, mono-PET, mono-paper and mono-aluminium.

Summary: currently there is a significant amount of ready-to-recycle flexible packaging appearing in residual waste samples, where it unlikely to be successfully returned to the economy and used again.

The research will analyse and compare the composition of flexible and rigid plastic packaging found in post-consumer household waste and recycling streams in seven key European markets. Fieldwork at two SUEZ sites in the UK took place in December 2020 and work on samples of waste from France, Germany, Italy, Netherlands, Poland and Spain is scheduled to take place in Spring 2021.

EndsNotes to editors

The Circular Economy for Flexible Packaging (CEFLEX) initiative is a collaboration of over 160 European companies, associations and organisations representing the entire value chain of flexible packaging. Together, we work to make all flexible packaging in Europe circular by 2025. More information, see: https://ceflex.eu/The Polyolefin Circular Economy Platform (PCEP) is a forum for all organisations and stakeholders in the polyolefin value chain to exchange ideas, showcase projects and work together to maximise innovation and value, so advancing the circular economy. PCEP is committed to transforming from a linear to a circular economy based on three principles; designing out waste; keeping products and materials in use; and recycling into high-quality new raw materials. More information, see: https://pcep.eu/

Petcore Europe is the association representing the complete PET value chain in Europe since 1993. Its mission is to ensure that the entire PET industry is well aligned to enhance its value and sustainable growth, to represent the PET industry before the European institutions and other stakeholders, to ensure that PET is positioned as an outstanding packaging material and recognised as environmentally sound, to support and validate innovative packaging solutions from a recycling perspective, and to work with all interested parties to ensure a continuous increase of PET post-consumer collection and recycling. More information, see: https://www.petcore-europe.org/

Styrenics Circular Solutions is the value chain initiative to increase the circularity of styrenics. The initiative engages the entire value chain in the development and industrialisation of new recycling technologies and solutions. It aims to strengthen the sustainability of styrenic products while improving resource efficiency within the circular economy. More information, see: http://styrenics-circular-solutions.com/

The Plastic and Laminate Squeeze Tube Recycling Project, managed by MORE Recycling, has funders from across the value chain that are seeking to collaborate with key stakeholders to ensure a path to recyclability for plastic and laminate squeeze tubes. The primary intent of the project is to gather and provide clear understanding of design of recycling requirements and to work through key barriers and solutions related to the collection and sortation of appropriately designed tubes in Europe. More information, see https://morerecycling.com/

Resource Futures is an employee-owned, independent environmental consultancy with a 30-year heritage in the waste and resources sector. Our services are designed to realise our vision of a sustainable world, with a focus on designing out waste and pollution, keeping products and materials in use and supporting and regenerating natural systems – a world designed according to circular economy principles.

Website: resourcefutures.co.uk

Twitter: @resourcefutures

Facebook: /resourcefutures

LinkedIn: https://www.linkedin.com/company/resource-futuresQuotes

“I am very excited by this project, which already in the early stages has brought enormous insight. Accurate understanding of the polyolefins collected via recycling and residual household waste streams, will play an important role in delivering PCEP’s commitment to enhance collection and sorting of polyolefins. This is a critical step to keeping these valuable materials in the circular economy and out of the environment. We are very happy to be partnering with CEFLEX, Petcore, SCS and More Recycling to develop this data for the full packaging value chain.”Venetia Spencer, Secretary General, PCEP

“Being a part of this study allows us to gather data about what kinds of plastic squeeze tubes are in the recycling and residual waste streams and how this packaging format compares with other plastic packaging in both streams. As we look to increase recyclable packaging and recycling overall, data on the packaging and products currently in the recycling and residual waste streams is critical to aid in our path forward.”

Stacey Luddy, COO, MORE RecyclingContact:

Audrey Koop

PR: CEFLEX

MAJIC Ltd

Tel: +44 (0)1424 777 783

Mob: +44 (0)7787 573 954Image

-

Wwp beauty names musa dias global chief...

Veteran global marketing professional joins leading beauty packaging and product supplier’s executive leadership team to bring forth empowering new innovations, design and strategies.

Los Angeles, CA – WWP Beauty, a leading full-service supplier to the global beauty industry and the source for everything beauty has named veteran senior-level global marketing executive Musa Dias as its new Global Chief Marketing Officer. Musa brings an extensive track record of driving and accelerating growth globally, both on the brand and supplier sides of the beauty industry, a multi-cultural background and a Luxury Brand Management MBA from ESSEC, France.

In her new role, Musa will be responsible for driving future-focused innovation through WWP Beauty’s marketing, creative and innovations teams and initiatives globally. Her leadership is expected to bring forth continued growth for the company, with new innovations and inspiring product launches from every category of the WWP Beauty business including packaging, formulation and accessories. Additionally, Musa will be responsible for upholding the newly established WWP Beauty pillars which promises that the company will provide their customers service in partnership and future-focused innovation at the global scale.

To WWP Beauty, Musa brings exemplary experience in marketing, product development and innovation across all beauty categories with a history of creating and launching new and award-winning product concepts. Her comprehensive experience in strategic planning, budgeting, brand management, operational management and category management has been showcased in several executive-level marketing roles.“Musa’s marketing expertise and deep understanding for our products and customer needs makes her the perfect fit for the WWP Beauty company. We are confident that she will not only help grow the company and strengthen its position in the supplier space, but will also empower her employees and our customers through her leadership skills and new and strategic innovations,” said Josh Kirschbaum, CEO of WWP Beauty.

“Musa is an innovative leader, and we are delighted to have her as the new Global Chief Marketing Officer at WWP Beauty,” said Jonathan Zhu – Managing Director at Bain Capital, which acquired WWP Beauty in 2018. “She brings an ideal mix of high-caliber global marketing experience, diverse technical background and strong business acumen, all of which will play a major role in increasing effectiveness of our global marketing strategy and accelerating our business growth.”

“I am thrilled to join WWP Beauty’s executive leadership team and am even more excited about the continuous innovation the company is bringing to the beauty industry and customers around the world. Working for a company like WWP Beauty that has such a strong purpose and commitment to sustainability, inclusivity and diversity is something I feel very passionate about and am proud to be a part of,” said Dias.

###

About WWP Beauty

WWP Beauty is committed to developing future-focused, sustainable solutions for the global beauty industry through close collaboration, exceptional agility, and unparalleled scale. The company’s full-service offering of formula, packaging and accessories, paired with their in-house manufacturing capabilities allow them to stand out as the source for everything beauty. Through a worldwide team of beauty experts that span across North America, EMEA and APAC, WWP Beauty offers their customers global support at the local level. To learn more visit our website at www.wwpbeauty.com.

Contact: Christopher Dale

Turchette Agency

(973) 227-8080 ext. 116

cdale@turchette.com

Megan Gunn

WWP Beauty

(973) 805-6500

megan@wwpinc.comImage

-

Big things come in small packages

In 2014 GKS introduced the unique fully modular construction method of its CP and UP packaging machine series.

-

We are pleased to have received the good...

Meet our D-Flex™ Ecosystem.

-

ema’s safety committee continues inve...

EMA is working closely with the company, with experts in blood disorders, and with other health authorities including

-

Aptar pharma and noble partner with dne ...

Aptar Pharma, a global leader in drug delivery systems, services and active packaging solutions and Noble, an Aptar P

-

25 years of pick & place machines from s...

Customers greatly appreciate this and benefit several times over.

-

Covid-19 foresight study: how have consu...

Beauty & Personal Care

-

Innovation and collaboration drive launc...

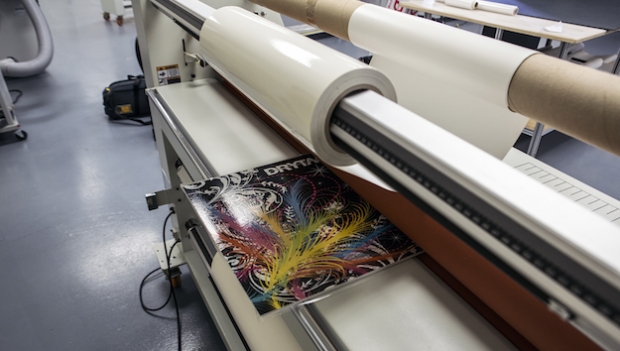

Cambridge, 11 March, 2021: Chinese OEM, King Tau has launched a new industrial-grade print engine, incorporating Xaar's advanced printhead technologies.

The ‘Magic Cube’ utilises Xaar’s unique TF Technology and High Laydown Technology to provide users with significant performance improvements for industrial inkjet printing.

Xaar’s TF Technology allows fluids to flow directly past the back of the printhead nozzle at very high flow rates. This prevents the nozzle from drying out, increasing its open time, and ensuring that the printhead is continuously primed for trouble free start-up, even after periods of non-use. High Laydown Technology enables the printing of textured effects onto flat surfaces up to 80um thickness on every pass, which delivers both reliability and higher productivity to the ‘Magic Cube‘ print engine.

As a pioneer in the ceramics and graphic sectors, Guangzhou based King Tau is a leading equipment manufacturer with more than 20 years’ experience in the development of solutions for many different industrial inkjet applications. The partnership with Xaar for the launch of the ‘Magic Cube’ print engine has further enhanced the company’s reputation for high quality and performance inkjet printer manufacturing.

"Our trust in the technical reliability and durable performance of Xaar’s printhead technology were key to our working together,” said Mr. Tong, Managing Director of King Tau.

“In addition, Xaar's unique specialist technologies deliver real value for our customers and differentiate our brand from competitive products."

The tie-up with King Tau underlines Xaar’s commitment to developing global partnerships and collaborative projects.

Xaar’s CEO, John Mills, said, "We are delighted to be working with an industry leader such as King Tau and welcome the opportunity to provide our products and technologies in China.

“Through our partnership we see great potential in delivering the quality, performance and reliability that the Chinese market demands."Ends

About Xaar

Together with our partners and customers, Xaar has been transforming the world of inkjet technology for 30 years – and we’re just getting started.

With a new leadership team, new technology and new products, we have an exciting roadmap for the future – that will help our partners unleash the true power of inkjet printing and open up a world of opportunities for their business.

We believe true innovation comes from collaboration, which is why all our teams work together in Cambridgeshire where industrial inkjet was born. Collaboration is at the core of our global partnerships too - whether we’re helping customers enhance their uptime or create production efficiencies from high-speed digitisation - we’re always innovating together.

We know that inkjet technology can not only maximise the efficiency of our partners’ businesses but help them evolve too. That’s why we go on a journey with our customers - offering expert insights and technical support every step of the way. Just like our printheads, Xaar’s partnerships are built to last.

Welcome to a whole new Xaar.

www.xaar.comContacts:

Xaar: Charlotte Baile

T: +44 1223 802151

E: charlotte.baile@xaar.com

Global ex China/USA: Nielsen McAllister,Simon Wildash / Richard Pettinger

T: +44 1332 293939

E: info@nmpr.co.uk

China: CommNow, Qianzi Che,T: +86 10 5096 1513

E: qianzi.che@commnow.cn

USA: Press+, Irvin PressT: +1 508-384-0608 E: irv@press-plus.com

Image

-

Blog post by jesper gustavsson, v-shape...

High-Quality In-Line Printing Now Available! We’re So Excited!

We have partnered with TrojanLabel®, an AstroNova Company, to integrate the TrojanLabel T2 high-volume digital inkjet press into our V-Shapes PRIME packaging machine! You can view a video showing how this works, and we hope you will share our excitement! [video link]

This fully integrated in-line printing solution delivers high-quality 1600 dpi printing that does justice to any brand and makes the manufacturing process faster since preprints of substrates are no longer required!

The TrojanLabel T2 uses food-safe water-based inks. When printing on the SIHL ARTYSIO flexible top layer of our sachets, the inks dry immediately, so there’s no slowdown in the up to 2,100 per hour sachets the PRIME can deliver.

Special thanks go to TrojanLabel and Memjet over the past year for their collaborative efforts and high-quality products and to SIHL for contributing their in-depth knowledge of substrates and coatings and how they interact with water-based inks from Memjet, whose printheads are used in the TrojanLabel T2 digital inkjet printer. Sihl not only offers a special coating that works with water-based inkjet inks, but also a multifunctional top film that, in addition to excellent printability with aqueous inkjet, also has great sealing properties to provide the best protection in along the shelf life period with barrier properties matched to the product being filled. Sihl offers films made for recycling.

Even better, we’ve worked with TOMRA, a designer of customized waste stream sorting solutions, who verified our sachets are accurately detectable as 100% polypropylene in the processing of industrial waste streams. This means they can be sorted in the waste stream for further appropriate processing, providing sustainability - an essential core value for us and for our customers.

We’re not stopping here. We’ve got lots of projects and launches in our planning in the next several months that will keep this technology and our innovation rolling forward, almost as fast as our manufacturing lines roll out sachets! So be sure to stay tuned. There’s definitely more to come !

More information is available at www.v-shapes.com and at:

Monika Dürr

duomedia

PR Consultant

monika.d@duomedia.com

+49(0)6104 944895

Jesper Gustavsson

V-Shapes

Business Development & Founding Partner

jesper.gustavsson@v-shapes.com

+39(0) 51 0185079Image

-

Amcor wins two flexible packaging associ...

Leading technologies recognized with two honors from the Flexible Packaging Association

Neenah, Wis. – Amcor is a leader in global consumer packaging, applying rich capabilities in material science and packaging technologies to solve complex challenges. Our innovative solutions anticipate needs in fast-changing markets to develop more responsible packaging solutions that unlock growth and win with both our customers and industry experts.

This year, Amcor is thrilled to be recognized for our leadership and celebrate two gold Flexible Packaging Association (FPA) achievement awards.

“It is exciting to be honored by the FPA for developing and producing leading packaging technologies for our customers,” said Amcor Chief Technology Officer William Jackson. “These technologies demonstrate our deep heritage and strategic commitment to innovation, and for delivering winning outcomes for our customers and the packaging industry at large.”

The FPA Achievement Awards have been showcasing industry innovation and advances that have changed the packaging industry since 1956. For recognition in expanding the use of flexible packaging, technical innovation, sustainability, printing and shelf impact, and packaging excellence, this year’s nominees included more than 200 entries across 75 package samples, which resulted in only 27 achievement awards across 20 packages, including:

Amcor dual-chamber pouch secures Gold achievement award for technical innovation

The Amcor dual-chamber pouch is a specialty multi-chamber pouch with a breathable membrane separating the chambers. The innovative packaging format consists of a peelable device chamber and non-peelable desiccant chamber. The desiccant is kept separate from the device by a vented film allowing the headspace in the two chambers to equilibrate. This leading solution is ideal for moisture sensitive applications such as drug-coated products which may be adversely affected by ambient moisture content. The non-peelable chamber also can be used to house other scavenging technologies including oxygen. Versions of the Amcor dual -chamber pouch are available for both irradiation and ETO sterilization.

“Amcor’s dual-chamber pouch technology is an excellent example of our commitment to using product innovation to advance patient safety in packaging,” said Amcor Healthcare Research and Development (R&D) Senior Director Brian Ingraham. “The technology eliminates the potential for contamination from scavenging sachets, with the device directly or within the surgical theatre.”

Shield Pack® clear high-barrier aseptic IBC liner garners Gold achievement award for technical innovation

Amcor’s innovative designers were faced with a challenge: The up-to-300 gallons of aseptic product within a bulk package could not be examined until dispensing occurred due to the bulk package’s metallized structure. Providing extended shelf life and a high barrier were key, while also targeting the clarity manufacturers want. Shield Pack® clear high-barrier aseptic IBC liner provides clarity and durability that distribution demands, while the multi-layer structure safeguards against moisture, oxygen and environmental contamination. This exciting technology extends distribution range, reduces transit failures, improves product quality and color, all while delivering other important attributes, including extended shelf-life, durability and the clear packaging format manufacturers want.

This year’s award ceremony was held virtually on March 10. Jackson accepted the awards on behalf of Amcor alongside members of the company’s core R&D team. Highlights from this year’s awards are available to stream.

Press Contact:

Mary Johnson, Marketing Communications Director

Amcor Flexibles North America

920-527-5134 | mary.johnson@amcor.comAbout Amcor

Amcor is a global leader in developing and producing responsible packaging for food, beverage, pharmaceutical, medical, home- and personal-care, and other products. Amcor works with leading companies around the world to protect their products and the people who rely on them, differentiate brands, and improve value chains through a range of flexible and rigid packaging, specialty cartons, closures, and services. The company is focused on making packaging that is increasingly light-weighted, recyclable and reusable, and made using a rising amount of recycled content. Around 47,000 Amcor people generate US$12.5 billion in sales from operations that span about 230 locations in 40-plus countries. NYSE: AMCR; ASX: AMC

www.amcor.com Image

-

Neopac develops plastic tube with reduce...

The new solution is available in plastic tube diameters ranging from 30-50mm, and in four substrate varieties: polyet

-

Partnership to explore the functional pr...

Origin by Ocean’s vision is to build a new value chain around the eutrophication problem of oceans – by harvesting al

-

Tesco partners with mondi on circular re...

Mondi uses the retailer’s corrugated waste to produce the EcoVantage grade, in which recycled and fresh fibres are co

-

Mondelēz international commits to furth...

“Our support for a more sustainable future for plastics is clear,” said Dirk Van de Put, chairman and CEO at Mondelēz