Aptar named one of barron’s 100 most s...

“We are honored to once again be included in Barron’s 100 Most Sustainable Companies and this is a testament to our s

“We are honored to once again be included in Barron’s 100 Most Sustainable Companies and this is a testament to our s

HiFlow E-Commerce features a metal-free pathway for optimal formula compatibility** and a showerproof design that red

Potential energy savings of up to 30 percent and a significant reduction in CO₂ emissions by as much as 90 or even 100 percent:

GEA’s Sustainable Energy Solutions (SEnS) offering integrates processes and utilities (refrigeration and heating) solutions, allowing GEA experts to develop optimization strategies for customers in diverse industries.

Numerous successfully completed SEnS projects from GEA show:

These optimizations reduce the customer’s energy footprint and running costs, without compromising output or the bottom line.

According to the United Nations, energy efficiency offers a potential 40 percent of the emission reductions required to help meet global climate goals.

Due to a growing number of rules and regulations and its own climate targets, there is an absolute need for the industry to reduce its carbon footprint and become more energy efficient overall. With cooling and heating traditionally accounting for anywhere between 50 and 90 percent of a plant’s entire energy consumption, it’s the ideal starting point for GEA’s SEnS initiative.

Unique SEnS approach helps customers to achieve their climate goals

GEA’s unique SEnS offering is a culmination of a broad processing portfolio and years of industry know-how combined with extensive refrigeration expertise. “SEnS supports customers in the food processing, dairy and beverage industries, helping them achieve their climate goals by making them more sustainable,” comments Kai Becker, since February 1, 2021, CEO Refrigeration Technology Division. As a global industrial technology provider, GEA will continue to strengthen its SEnS offering in 2021.Using the SEnS approach, GEA will promote the increased adoption of sustainable solutions which drive down energy consumption and reduce carbon emissions while helping customers from diverse industry sectors slash their operational costs.

Typically, process plants are designed in a way that separates processes from utilities (cooling & heating), rather than considering them as a whole. Customers often place tremendous focus on the design or optimization of a particular process, overlooking the bigger picture. GEA combines these two parts and ensures that they work well together.

“GEA has developed a structured holistic and proven approach that begins with analyzing the customer’s precise energy requirements, then making process optimizations and including utilities in the equation. By connecting heat pump technology to manufacturing processes, the GEA experts ensure energy is moving circularly, rather than being wasted”, says Ulrich Walk, Chief Service Officer (CSO) – Refrigeration Technologies.

Cross-functional teams and one point of contact

Each GEA SEnS project includes a single point of contact enabling customers to achieve genuine and proven reductions in energy consumption and their carbon footprint. The SEnS process is backed up by a cross-functional engineering team with experts from dairy, food or beverage processing as required, as well as team members with refrigeration (heating & cooling) expertise in diverse processing industries. Each project considers the customer’s business parameters and ambitions, formulated as measurable KPIs, against which the installation must deliver.

Involvement at an early stage in the planning process

When it comes to plant upgrades, GEA recommends that customers should integrate the GEA experts as early as possible in the design process. Doing so can mitigate potential frustrations later on as the solution will be more closely aligned with expectations at a very early stage. Another big advantage: This early involvement will lead to more cost-efficiency. “GEA has decades of experience helping customers improve the efficiency of their plants – and now the process has been made even easier”, concludes Becker.

Corporate Media & Press:

Dr. Michael Golek

Peter-Müller-Str. 12, 40468 Düsseldorf

Tel. +49 211 9136-1505

The world is returning to a new sense of connection and six clear bright colors represent a can-do attitude to positive global change

Spartanburg, S.C. – In 2022 care and respect are high on the agenda as we step out with a brighter attitude and deeper optimism for global change. As the world recovers from a fragile time of vulnerability people have an Emerging Confidence that positive choices can make a difference in our daily lives, with care and respect high on the agenda.

Milliken’s ColorDirection 2022 Emerging Confidence offers brands a way to reflect these values, and society’s newfound optimism, channeling positive consumer choice with the hopeful imagery of bright and optimistic colors in product packaging.

Welcoming Sunshine is a fresh yellow that gives a bright optimism to your product range and a new feel to your brand. It brings the positive warmth of mornings and the energy of light to your portfolio, laying out the potential for new consumer joy.

Soothing Heat is a strong, warm orange that directs attention to any product. Evoking the flame of a log fire or the nostalgic crispness of bright autumn leaves, Soothing Heat reassures, prepares and energizes.

Blossoming Joy is a color that evokes the happiness of freshly-cut flowers brought indoors from a summer garden, imagining exciting new possibilities of passion and growth. It is urgent and active, reminding our eyes to smile and look forward.

Radiating Richness will add a sense of comfort and depth to your color range for positive products. It is a balanced color that is less about luxury and more about self-care, inclusion and optimism for consumers looking for meaning.

Freshening Shoots is a bright, vibrant green symbolizing new growth and nature combined. Few colors suggest life better than this, saying it is time to start over in an ecological, sustainable and thoughtful way.

Connecting Lives is a color that brings tranquility, trust and peace to front and center. It reminds us that we all share our skies and waters and the feelings they evoke are universal. It’s a strong blue of togetherness, breath and clarity that signals freshness and positive action.

With brands looking ahead to refresh their image and portfolio to meet the growing need for positive choices, Milliken’s ColorDirection 2022 Emerging Confidence range of globally leading colorants will give your products the eye-catching confidence to sway consumers as they look for companies to believe in.

Milliken’s portfolio includes:

Liquitint™ customized colorants that combine dynamic colors with excellent processability for multiple applications including home and laundry care. Among the many reasons top manufacturers opt for Milliken’s Liquitint polymeric colorants are: solubility, compatibility, versatility and stability. These water-soluble and non-staining colorants are compatible with the most challenging active ingredients, including additives and higher perfume levels;

Liquitint Agro, advanced colorants for fertilizer. This range of non-staining liquid colorants provides a broad spectrum of color options with low inventory requirements and easy blending, thus reducing waste and increasing saving potential for your operations;

ClearTint™ color concentrates for NX® UltraClear™ polypropylene (PP) add vivid, transparent color and are compliant with safety requirements for food packaging;

Reactint® polymeric colorants for polyurethane (PU) add appealing color to products without affecting the physical properties of the material;

Milliken’s KeyPlast® line offers a spectrum of bright, high performance colorants for a multitude of polymer and resin systems. These include ABS, PET in transparent, food-contact applications, as well as other transparent amorphous polymers such as polystyrene (PS), polycarbonate (PC) and acrylic (PMMA);

KeyPlast RESIST™ is a spectrum of bright, high performance colorants, specially designed for coloring engineering polymers such as polyamides (PA), polybutylene terephthalates (PBT), polypthalamides (PPA), polysulfones (PSU), and other high-heat glass filled and flame retardant resins and alloys. These colorants offer improved weather resistance and light fastness, are high purity and perform well in the high-temperature processing and application conditions typically associated with high-performance polymers.

Learn more on chemical.milliken.com.

About Milliken

Materials science expert Milliken & Company knows that a single molecule has the potential to change the world. With innovative solutions across the textile, flooring, specialty chemical, and healthcare industries, Milliken answers some of the world’s greatest challenges. Named to the World’s Most Ethical Companies list by Ethisphere Institute for 14 years, the company meets the moment with an unwavering commitment to delivering sustainable solutions for its customers and communities. Eight thousand associates across 46 locations globally rally behind a common purpose: to positively impact the world for generations. Discover more about Milliken’s curious minds and inspired solutions at milliken.com and on Facebook, Instagram, LinkedIn and Twitter.

Reactint, Keyplast, NX, Milliken, and the Milliken logo are registered trademarks of Milliken & Company in the US, E.U. and elsewhere.

Liquitint, ClearTint, KeyPlast RESIST and UltraClear are trademarks of Milliken & Company.

###

MEDIA CONTACT

Veerle de Wolf

veerle.dewolf@milliken.com

+32 9 265 1136

Sean Norton

sean.norton@milliken.com

+1 864 503 6582

Zina Zhu

zina.zhu@Milliken.com

+86 21 61451736

Josina van der Velden

jvandervelden@emg-marcom.com

+31 164 317 014

Honeywell UOP selected GEA Refrigeration Technologies’ oil & gas team to supply engineered compression packages for a tail gas application at a refinery in Azerbaijan. Utilizing GEA's most powerful screw compressor, the GEA model XH, the systems are designed for a modernization program at the refinery.

Project overview

GEA's tail gas packages were selected for the project by Honeywell UOP as part of their Pressure Swing Adsorption (PSA) technology to supply high-quality hydrogen for the modernization of the Heydar Aliyev Oil Refinery (HAOR) in Baku, Azerbaijan. Pure hydrogen is essential to the refining process, where it is used to decontaminate oil and facilitate catalytic processes that produce clean-burning fuels, including those that meet Euro V standards for vehicle emissions.

The PSA technology will help Azerbaijan meet the growing domestic demand for transportation fuels that meet the Euro V standards. Hydrogen technology is an important element of modernization program that will help the refinery in Azerbaijan to remain among the most advanced refineries in the region, further improving environmental protection along with the quality of life in Azerbaijan.

The modernization enables the refinery to process 7.5 million metric tons per annum of crude oil blended from local sources. Hydrogen is key in the refining process, being produced as a byproduct of refining and intentionally from a steam methane reformer. Honeywell UOP's PSA technology purifies this hydrogen so it essentially can be recycled into the refinery to remove impurities and to perform catalytic processes that transform crude oil into clean fuels and other products.

Tail gas treatment

The purpose of these tail gas compression units is to receive the tail gas – a gas mixture composition with up to ~70% hydrogen – from the PSA System and keep stable pressure at the PSA discharge. Received gas is compressed up to 6,7 bar(g) and then cooled down to 40°C in the after cooler before it is returned to the customer’s system.

These units are based on an oil-flooded screw compressor and the oil is separated from the tail gas into two oil separators (main and final) in order to deliver the gas with less than 1 ppm of oil content.

As an oil-flooded screw compressor, the oil circuit is provided for lubricating the internal part of the screw compressor. The oil circuit comprises two oil pumps (one in standby), a pressure control valve to keep the oil pressure constant and an electro-pneumatic three-way control valve to maintain the oil flow to the compressor at a fixed temperature. The oil circuit also comprises two oil coolers (one in standby) with a common inlet and outlet line for the cooling water system. The discharged oil at high temperature, recovered in the oil separator, is cooled down by using cooling water as a medium.

All vessels and all heat exchangers are designed and manufactured according to ASME (American Society of Mechanical Engineers) and TEMA R (Tubular Exchanger Manufacturers Association). GEA also provided the personnel protection with rock wool and aluminum and winterization of the entire oil circuit.

Technical data

Compressor: GEA oil-flooded, single-stage screw

Model: GEA XHA-XH36A-28

Capacity: 11427,0 Sm3/h

Gas Handled: Tail gas

Suction Pressure: 0,31 bar(g)

Discharge Pressure: 6,7 bar(g)

EM installed: 1.370 kW

GEA Refrigeration Technologies’ global oil & gas team provides custom process refrigeration and gas compression solutions for a wide range of industries and applications.

Honeywell UOP is a leading international supplier and licensor of process technology, catalysts, adsorbents, equipment, and consulting services to the petroleum refining, petrochemical, and gas processing industries.

Corporate Media & Press:

Dr. Michael Golek

Peter-Müller-Str. 12, 40468 Düsseldorf

Tel. +49 211 9136-1505

Düsseldorf (Germany), February 24, 2021 — Companies benefit particularly strongly from the ever-evolving GEA Omni control panel. GEA is discussing the subject of digital control of industrial refrigeration systems in its first Cooling Club webinar of the year entitled, “Improve Your Bottom Line with the Energy-saving GEA Omni Control Panel”. The webinar will take place from 4:00- 5:00pm Central European Time on Thursday, March 18, 2021.

Click here to register.

This free-of-charge webinar is open to industry professionals who will have the opportunity to listen to, and interact with, GEA experts Tom Eelen and Wilco Kanters to learn more about how advanced digital control panel technology can improve bottom-line results by minimizing energy use and reducing production downtime.

Topics of the virtual Cooling Club:

* How the industry is benefiting from GEA’s latest control panel innovation;

* Ways by which refrigeration system efficiency can be increased;

* How GEA Omni can reduce production downtime;

* Demonstration of GEA Omni’s capabilities and ease of use;

* Updates on GEA Omni’s most-recently-added and soon-to-be-added features like artificial intelligence;

* Insight into how companies can benefit from this advanced digital technology.

The presenters will draw from their decades-long experiences in the industrial refrigeration space and provide eye-opening insight into the path ahead for users of industrial refrigeration systems.

Speakers:

Tom Eelen has been working in refrigeration working in refrigeration system sales for more than 20 years. He joined GEA in 2004 where he is, after several positions, Head of Sales and Sales Support for Belgium, the Netherlands and Luxembourg. His focus is on sustainable energy solutions in cooling and heating for industrial processes. A graduate of KATHO, member of the K.U. Leuven Association, in Kortrijk, Belgium, Tom Eelen holds a diploma in refrigeration and air conditioning.

Wilco Kanters has been working in refrigeration systems for more than 25 years. He joined GEA in 1991 and currently serves as Product Manager System Panels and is responsible for the GEA Omni control panel in Europe. His focus is on specialized process automation for refrigeration and he has introduced a wide range of new products based on the GEA Omni control panel platform.

Corporate Media & Press:

Dr. Michael Golek

Peter-Müller-Str. 12, 40468 Düsseldorf

Tel. +49 211 9136-1505

In case of publication, please submit two copies of each of the published items for our archives.

About GEA

"Engineering for a better world" is the driving and energizing principle connecting GEA’s total workforce of approximately 18,500 employees. As one of the largest systems suppliers, generating group revenues in the amount of 4.9 billion euros in 2019, GEA makes an important contribution to a sustainable future with its solutions and services, particularly in the food, beverage and pharmaceutical sectors. Across the globe, GEA’s plants, processes and components contribute significantly to the reduction of CO2 emissions, plastic use as well as food waste in production. GEA is listed on the German MDAX and the STOXX® Europe 600 Index and also included in the DAX 50 ESG and MSCI Global Sustainability indexes.

Your contact details are stored in our central CRM-system exclusively for sending press releases. In our data protection notice we inform you about the GEA data protection guidelines. If you do not want to receive any further information from GEA, please send an email to pr@gea.com.

GEA Group Aktiengesellschaft

Phone 49 211 9136-1492 • Fax 49 211 9136-3-1492 • gea.com • Peter-Müller-Str. 12, 40468 Düsseldorf

Label Academy, the global training provider for the label and package printing industry, is to host its third virtual master class aimed at an international audience in March. This latest learning opportunity will cover brand protection for the first time.

As with the previous two virtual master classes, Brand Protection will be presented by Labelexpo’s strategic director Andy Thomas-Emans, who will be joined by guest speakers from companies including the American Apparel and Footwear Association, Avery Dennison, Digimarc, HP, the International Hologram Manufacturers Association, INX International, Mercian Labels, Vandagraf, VerifyMe and Vicki Strull Design. The master class will also be split into two two-hour parts; Part One will take place on Tuesday 23 March, and Part Two takes place on Tuesday 30 March.

Part One will present a range of brand protection perspectives, with sessions including: an overview of the counterfeiting market, a brand owner perspective on what’s important, the brand consultant perspective, and the label converter perspective on the challenges of meeting a brand owner’s needs. Part Two will focus on some of the key overt and covert technologies, with sessions covering inks, anti-tamper materials, print processes, RFID and NFC tags, holograms and watermarking.

Thomas-Emans said: “We are delighted to grow our online learning portfolio with this latest educational opportunity covering our global industry’s most pressing topics. This is the first time we’ve hosted a master class on brand protection, which has never been more crucial than now. Consumer demand for label and package printing continues to rise, and with it, the thriving counterfeiting market at all levels of the supply chain.

“It’s important therefore that anyone involved in label and package printing production is aware of the scale of the challenge, the possible pitfalls, and has a full understanding of the key technologies tackling this.”

Speakers include Dr Paul Dunn, chair, International Hologram Manufacturers Association, who said: “This is a great opportunity to provide an insight into the technology evolution that has occurred in recent years in the development of holograms and optical devices in general for product security and authentication. The diversity of technologies today offers a wide choice of optical security solutions to add value and security to any Brand product.”

Michael Welch, Senior Product Manager, Durables (North America), Avery Dennison, added: “The global Covid-19 pandemic put a spotlight on maintaining consumer safety and has amplified the need for anti-tampering materials and packaging. We're excited to share new materials, applications and use cases in the virtual master class.”

The Brand Protection virtual master class costs 95 USD per session. For more information and booking, visit www.labelsandlabeling.com/label-academy/master-classes.

- Ends -

For further information about the Label Academy, please contact:

Helen Stoddart, conference manager, Labelexpo Global Series.

Email: hstoddart@labelexpo.com

Notes to editors:

About the Label Academy

The Label Academy is a global training provider and on-the-job resource for the label and package printing industry. It was pioneered by industry expert Mike Fairley in response to a reduction in the number of dedicated printing colleges and the need to standardize the label industry’s very specialized training and education across the world.

The Label Academy’s in-depth and expert-led master classes in English have proved extremely popular around the world at Labelexpo trade shows over the last few years, covering a wide range of key topics in the label and package printing industry. These have included: shrink sleeves; and inks, coatings and varnishes.

Previous virtual master classes have covered digital printing technology, and flexible packaging.

The Label Academy is part of Tarsus Group - the international media group with interests in exhibitions, conferences, publishing and online media including Labelexpo Global Series, and is endorsed by FINAT, TLMI, LMAI, Turkish Label Association and BPIF.

Brand Protection, Security Labeling and Packaging, by Jeremy Plimmer, is available to purchase on Amazon.com and its regional sites.

How attitudes to packaging and its functionality have changed over the past seven years, based on a detailed survey of 1,000 UK consumers, is the subject of a new White Paper from leading packaging tapes provider Essentra Tapes.

The full results were first revealed at a recent ThePackHub webinar, where Essentra Tape’s head of marketing & development, Ian Beresford, unveiled consumers’ latest opinions and compared them to previous research in 2013.

While the survey showed a 15% decrease in consumer packaging frustrations during this time, at 70% the figure remained high, with difficulty in opening packs still a major gripe among respondents. However, environmental concerns and the huge growth of e-commerce have had a significant influence on consumer opinions, and overpackaging is now seen as the number one frustration.

Not surprisingly, the Covid-19 pandemic has also had an impact, with the hygienic benefits of packaging becoming more important.

Age was still a key factor, and the research confirmed that ease of access continued to be a particular problem for the over 55s. Access was also the deciding factor behind consumers’ most and least favourite pack styles. The three most frustrating packs all lacked opening devices with the hard plastic clamshell retaining its top spot from 2013, while juice cartons with screw caps and cans with ring pulls were the number one and two most pleasing packs.

In addition, consumers highlighted the importance of sustainability within packaging and ranked recyclability as their number one issue. Packs that are easy to recycle are what consumers care about and providing simple, clear instructions and the necessary infrastructure to help with this is key. It also appears that consumers are starting to expect packs to be designed to be more sustainable, with only a third saying they would be prepared to pay more for sustainable packaging.

“Our latest research shows that the image of packaging among consumers has improved somewhat since 2013 but there is clearly still work to do,” commented Beresford. “In particular, it underlines the need for packaging manufacturers to continue to adapt their solutions in line with current market trends and consumer attitudes to sustainability, making it easier for them to make the right choice.

“It is also clear that the need to meet this wide variety of consumer needs means that packs often have to be multi-functional. For example, a tear tape for easy-opening can also provide a means of communication between a brand and its consumers; a resealable pack can combine user-convenience with product protection, portion control and the minimisation of food waste.

“Such additional benefits can help to reinforce positive perceptions about a product and support brand image and positioning.”

Key findings from the survey included:

Too much packaging is now the number one frustration with 58 per cent of consumers highlighting this issue, an increase from 49 per cent in 2013.

57 per cent of those surveyed cited ‘Difficult to open’ as their top frustration and 48 per cent said that they had to use knives or other tools to get into packs. This compares to 61 per cent and 69 per cent in 2013.

56 per cent of respondents said there was too much packaging in home delivered goods and 40 per cent highlighted the amount of waste this generates.

Over 50% of consumers are very or extremely concerned about the hygiene of goods in supermarkets and takeaway food deliveries as a result of the pandemic.

The top ten most frustrating and pleasing packs were:

Essentra Tapes is continuing to promote ‘Packaging with Purpose’ that not only enables brand owners to satisfy the need for functionality but also delivers additional benefits that will help to strengthen a brand’s relationship with its consumers.

“Packaging is the key medium by which to communicate the brand, and our research shows that consumers respond positively to packs that serve a clear purpose,” concluded Beresford.

“When packaging works, it makes people feel good about the product; conversely, a poor pack can have a deeply negative effect on their perception of the brand, affecting re-purchase decisions.

“Packaging solutions that focus on opening, closing, informing and protecting can resolve many of the typical consumer pack frustrations and at the same time deliver added value and enhance brand image, to the extent of becoming an integral part of the brand experience.”

The Essentra white paper is available to download free at www.essentra.com/en/capabilities/tapes.

Ends

Note

Essentra Tapes undertook an online survey of 1,000 UK consumers between the ages of 18 to 88 in Q4 2020 regarding their opinions on packaging. Results from the survey were compared to Essentra’s previous independent research held in 2013.

Ian Beresford is available for print or broadcast interviews. Please contact Simon or Jack at Nielsen McAllister to arrange. info@nmpr.co.uk or 01332 293939

ABOUT ESSENTRA TAPES

https://www.essentra.com/en/capabilities/tapes

Essentra Tapes is part of Essentra plc and is a global provider of tapes that deliver benefits to consumers, combining easy opening and closing for a wide range of products with creative design & print to deliver brand communication and protection - all promoted under four core themes of Open, Close, Inform and Protect.

Significant experience in the field of security technologies also enables us to combine overt and covert security into our tapes to protect brands and products. Supported by a global manufacturing base, in-house design studio, R&D facilities and multi-million-pound print facilities, Essentra Tapes is positioned to deliver the very best in quality, service and reliability to help make customers’ and consumers’ lives easier.

For Essentra Tapes sales enquiries please contact:

Tel: +44 (0)115 975-9000

Email: sales@essentratapes.com

Website: www.essentra.com/en/capabilities/tapes

LinkedIn: www.linkedin.com/showcase/essentra-tear-tapes/

For Essentra Tapes - media enquiries please contact:

Simon Wildash or Jack Readman, Nielsen McAllister

Tel: +44 (0)1332 293939

Email: info@nmpr.co.uk

Schreiner Group has been committed to climate protection and sustainability for many years. As a result of its environmental programs, the high-tech company has reduced its carbon dioxide emissions by 65 percent and increased the utilization of renewable energies to more than 50 percent of its total energy consumption in recent years, among other things. Now the family-owned business has made another move towards a climate-neutral future by having installed and activated nine charging stations for electric vehicles at its headquarters in Oberschleissheim.

Having produced solar power on the roofs of its parking garages for a long time, Schreiner Group is now able to feed sustainable electricity directly into electric mobility as well. For this purpose, the company installed a total of nine EV charging stations on its business premises at the beginning of the year. As a result, Schreiner Group will also increase the share of electric vehicles in the company’s fleet during the course of 2021.

In addition to charging fleet vehicles and company cars, the new stations will be available to visitors and employees for charging their vehicles. “I am delighted that the installation of the EV charging columns enables us to do even more for climate protection than we already have been,” says CEO Roland Schreiner, “and am convinced that this will also provide our employees with another incentive for buying electric vehicles.”

Power supply to the charging columns posed the greatest challenge during the installation project. Since many of the EV charging stations are located in one of Schreiner Group’s parking garages for employees, a dedicated power supply line had to be installed. This requirement was successfully met with the grid operator’s support.

For more information, please contact:

Susanne Höppner,

Corporate Communications

Phone +49 89 31584-5852,

Since the beginning of our partnership, we’ve enabled the recycling of over 625,000 pouches that otherwise would have

For Enval, the ultimate aim of the project is to see our first recycling plants in the United States.

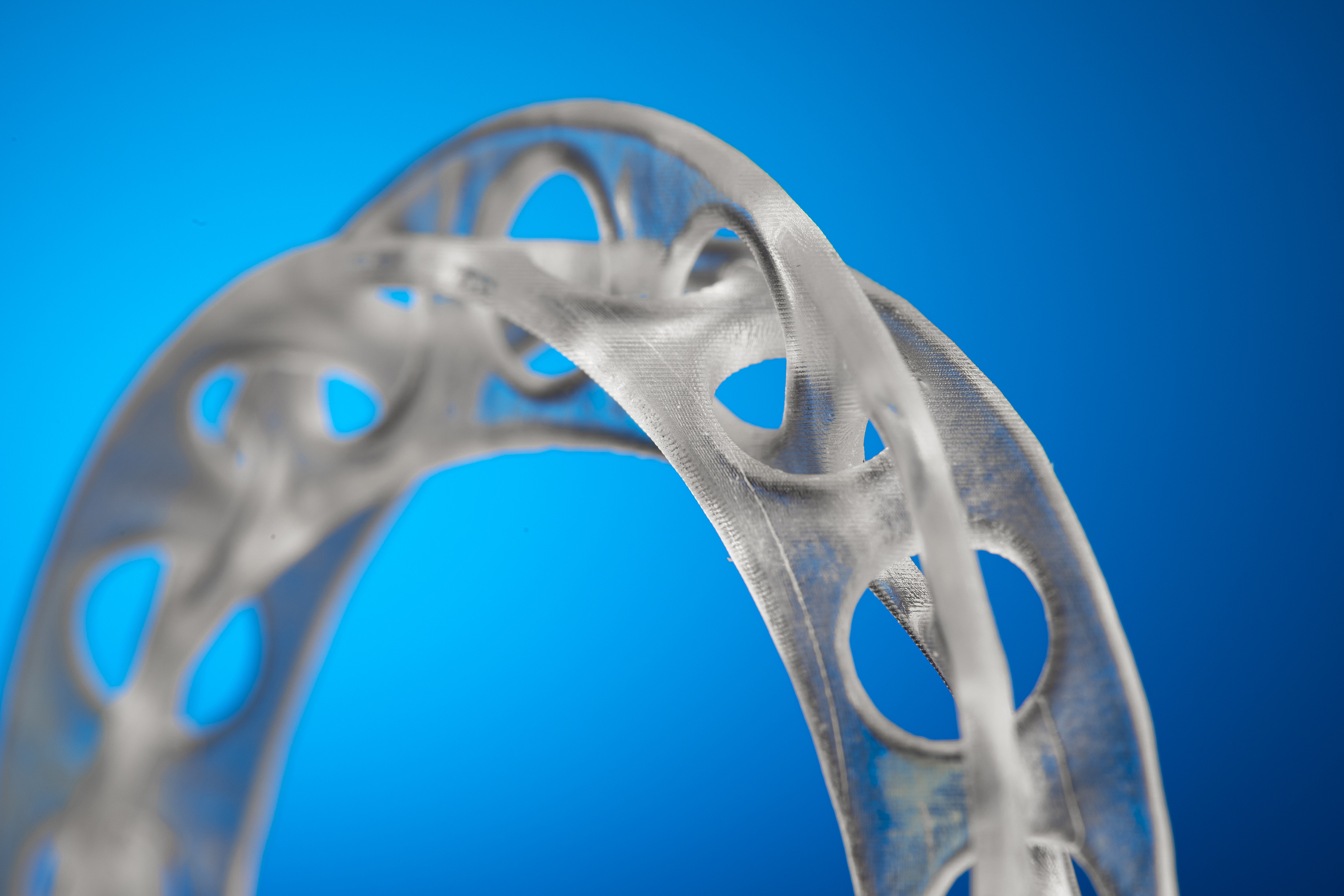

February 23, 2021 - Leading inkjet technology company, Xaar, and novel jetting technology provider Meta Additive, will demonstrate how Xaar’s technologies and collaborative approach are enabling ground-breaking applications, at this month’s FuturePrint virtual conference.

Titled, ‘Pushing the boundaries of what’s possible’, Graham Tweedale, General Manager of Xaar’s printhead business, will review how Xaar’s unique technologies are pushing inkjet and 3D printing beyond its traditional applications into increasingly new areas.

Highlighting the culture which exists to drive creativity and innovation at Xaar, Graham will focus on three of Xaar’s technologies – TF Technology, High Laydown Technology and High Viscosity – and explain their contribution to moving beyond the conventional limits of inkjet printing.

In addition, Dr Kate Black, Chief Technology Officer at Meta Additive, will introduce its innovative binder jetting process and explain why the collaboration with Xaar has been an important part of their development process.

Graham commented, “The FuturePrint conference focuses on new technology that enables production to adapt to fast-changing, new markets, and if the last year has shown us anything, it’s the need for agility and innovation.

“Our work with Meta Additive and its binder jetting invention is as creative as it is relevant to today’s evolving manufacturing environment, and above all demonstrates the role that inkjet technology and collaboration between two forward-thinking businesses is playing in pushing the boundaries of inkjet.”

The two-day FuturePrint Virtual Conference will highlight the latest developments within industrial, packaging, labels, commercial and wide-format print technologies designed to meet the needs of customers in 2021 and beyond.

Graham and Kate’s presentation takes place on February 26th at 15.00GMT / 16.00CET. The session is open to all and can be attended by pre-registering at www.futureprint.tech.

About Xaar

Together with our partners and customers, Xaar has been transforming the world of inkjet technology for 30 years – and we’re just getting started.

With a new leadership team, new technology and new products, we have an exciting roadmap for the future – that will help our partners unleash the true power of inkjet printing and open up a world of opportunities for their business.

We believe true innovation comes from collaboration, which is why all our teams work together in Cambridgeshire where industrial inkjet was born.

Collaboration is at the core of our global partnerships too - whether we’re helping customers enhance their uptime or create production efficiencies from high-speed digitisation - we’re always innovating together.

We know that inkjet technology can not only maximise the efficiency of our partners’ businesses but help them evolve too. That’s why we go on a journey with our customers - offering expert insights and technical support every step of the way. Just like our printheads, Xaar’s partnerships are built to last.

Welcome to a whole new Xaar.

www.xaar.com

Contacts:

Xaar: Charlotte Baile

T: +44 1223 802151

E: charlotte.baile@xaar.com

Global ex China/USA: Nielsen McAllister, Simon Wildash /

Richard Pettinger

T: +44 1332 293939

E: info@nmpr.co.uk

China: CommNow, Qianzi Che,

T: +86 10 5096 1513

E: qianzi.che@commnow.cn

USA: Press+, Irvin Press

T: +1 508-384-0608 E: irv@press-plus.com

Company’s contribution to “Backpacks of Hope” mission provides emergency supplies and resources to local residents.

Camden, NJ – Rondo-Pak, LLC/Contemporary Graphic Solutions, a leading provider of printed components and quality folding cartons for the pharmaceutical, medical device and consumer industries, is proud to have participated in “Backpacks of Hope”, a community aid initiative in Puerto Rico formed in response to the series of earthquakes that hit the island in December 2019. Organized by EcoExploratorio, a local science and technology center in San Juan, the initiative aims to develop resilience and preparedness against natural disasters in communities across Puerto Rico.

“Backpacks of Hope” seeks donations to provide much-needed emergency supplies, resources and support to hundreds of communities affected by the recent natural disasters across the island. Rondo-Pak’s contribution went towards providing 54 backpacks filled with safety items such as thermal blankets, first aid kits, emergency water packs, school supplies and educational literature on how to prepare for natural disasters like earthquakes and climate change. The backpacks were given to 50 families in three municipalities including those affected by the series of earthquakes in southern Puerto Rico that began in December 2019, along with families affected by a series of flash floods in August 2020.

Due to the COVID-19 pandemic arising shortly after the company’s donation, distribution of the backpacks was delayed but completed in January 2021.

As a HUBZone company with a facility in San Juan, Rondo-Pak has become an integral part of the community and employs many residents. With a local connection and valued employees in the areas affected, contributing to this cause was an important one for the company.

“We are pleased to have been able to contribute to such a worthy cause thanks to the generous donations of our Rondo-Pak employees,” said Tim Moreton, CEO of Rondo-Pak/CGS. “The several recent natural disasters in Puerto Rico have brought tragedy to many communities, and we trust that the backpacks donated will bring hope and necessary resources to those affected.”

“Through these community aid initiatives, the EcoExploratorio has been able to bring help and support to hundreds of communities across the island with the goal of providing necessary tools that empower and develop resilience in both students and their families,” said Jenny M. Guevara Rivera, Executive Director of EcoExploratorio, Inc. “It is with the gracious help of organizations such as Rondo-Pak that we are able to make a difference to those that need it most.”

# # #

About Rondo-Pak

Rondo-Pak/Contemporary Graphic Solutions is a global print and packaging specialist whose unique blend of capabilities and forward thinking yields present-day solutions for tomorrow’s challenges. Strategically aligned with Körber Pharma to link packaging equipment, materials, and software, Rondo-Pak provides a comprehensive assortment of marketing and packaging solutions to address challenges facing the pharmaceutical industry, including global brand management, packaging efficiency, and supply chain optimization.

In combination with a wide range of printed materials such as inserts, leaflets, medication guides and regulated marketing materials, Rondo-Pak’s packaging innovations address precise requirements for compliance, child resistance, anti-counterfeiting, e-pedigree and more. For more information, visit www.rondopak.com.

client: Rondo-Pak, LLC

contact: Christopher Dale

Turchette Agency

(973) 227-8080, ext. 116

cdale@turchette.com

Rondo-Pak/Contemporary Graphic Solutions, LLC

(800) 575-4238

info@rondopak.com

Latest addition to company’s EcoDesign portfolio of sustainability-minded tubes uses up to 30% less virgin materials

Oberdiessbach, Switzerland – Hoffmann Neopac, a global provider of high-quality, responsible packaging for a broad array of industries and applications, has introduced a lighter plastic tube solution comprising up to 30% less virgin materials. The latest addition to the company’s EcoDesign series of eco-friendly tubes, the new LIGHTWEIGHT TUBE aligns with packaging industry desires to minimize carbon footprint and materials waste.

Brand owners in various sectors – particularly health & beauty but also pharma– are increasingly looking to reduce or replace the use of virgin plastic packaging materials to enhance their products’ sustainability profiles. The use of such lighter-weight packaging reduces both shipping costs and extended producer responsibility (EPR) fees.

Neopac’s LIGHTWEIGHT TUBE is available in plastic tube diameters ranging from 30-50mm, and in four substrate varieties: Polyethelene and Recycled tubes, each with or without EVOH barrier. Materials reduction is most prominent in the tubes’ wall thickness, which has been reduced from 0.5 mm to 0.35 mm without sacrificing exemplary haptics. Low profile closures are already in the pipeline to achieve maximum weight reduction in plastic tubes.

Neopac estimates that, in its own packaging manufacturing operations, the new tubes will eliminate the need for as much as 4.6 tons of HDPE materials per one million tubes produced. This translates to an overall carbon footprint reduction of about 8.6 tons of CO2 per million tubes manufactured.

“Finding ways to reduce the overall amount of materials is mandatory for packaging suppliers to move toward ambitious sustainability goals,” said Cornelia Schmid, Head of Marketing for Hoffmann Neopac. “Always, a challenge is to boost a package’s eco-friendliness without sacrificing product protection or aesthetics. The new LIGHTWEIGHT TUBES are viable solutions for brand owners in a number of industries, helping meet increasing consumer desires for comprehensive product sustainability.”

Other solutions in Neopac’s EcoDesign portfolio includes RECYCLED TUBE featuring 70% recycling material, 64% of which is PCR; Sugarcane Tube, made from renewable raw materials; and PICEA™ wood tube, comprised of 95% renewable material in the tube body and shoulder – including 10% of spruce wood from wood waste in sawmills.

# # #

About Hoffmann Neopac

Hoffmann Neopac is a privately-owned company, headquartered in Thun, Switzerland. The group produces high-quality metal and plastic packaging in six locations: HOFFMANN tins in Thun and in Holland; Polyfoil® and plastic tubes with NEOPAC in Switzerland, Hungary and the US; and 3D Neopac in India. Its longstanding customers include pharmaceutical, cosmetics and consumer goods manufacturers in the European, North American and Asian markets.

Including all facilities, Hoffmann Neopac employs 1,250 personnel and has a capacity of 1.3 billion tubes and 400 million tins. The company is dedicated to sustainability in both its manufacturing processes and corporate culture, including a dedicated eco-conscious packaging portfolio. For more information, visit www.neopac.com.

client: Hoffmann Neopac

contact: Christopher Dale

Turchette Agency

(973) 227-8080 ext. 116

cdale@turchette.com

Pharma/nutra manufacturing solutions giant, ACG, added another specialist division to its integrated global offering with the official inauguration of its first ACG Laboratories site – a lab for process development in Shirwal.

The new facility is set to provide ACG's customers and partners with a research, development, testing, and training environment dedicated to the collaborative exploration of all aspects of oral solid dosage manufacturing.

As an extension of ACG's broader customer service offering (which includes process equipment recommendations and solutions, formulation and scale-up support, new product development and validation, and technical training), the new lab now allows ACG clients to explore and solve their manufacturing needs and challenges in a dedicated and state-of-the-art space. The facility also answers a growing customer need for training and assistance with clinical trials and development projects.

The lab houses a dedicated R&D space for small-scale development, and a pilot area for scale-up and process optimisation studies. It is equipped to accommodate multiple projects at a time.

The Shirwal Process Development Lab is led by a fifteen heads-strong team of industry experts, covering every manufacturing niche and application. Among them are specialists in areas including fluid bed and high shear mixer granulation, bottom spray pellet coating and drying, tablet compression and coating as well capsule filling. To date, this team has been responsible for the development of over 3,500 formulations.

On the launch of ACG Laboratories, Dr Marcus Michel (CEO of ACG Engineering) said: "We believe in constantly trying to make the life of our customers and end users easier and better. The lab's multi-purpose functionality allows us to support our customers in a way of an aligned partnership throughout the product development process. It provides a 'go-to' knowledge hub for continuous support of the customer in various stages of product manufacturing across different OSD applications. It is also a benchmark for our industry. Recent situation has shown us how critical close collaboration and agility have become to reaching the end-user’s requirements. If ACG can be part of that evolution with our clients, then we’ll truly be living up to our ‘Make it better’ mission."

About ACG

ACG has been providing innovative integrated solutions to the global pharmaceutical and nutraceutical industries for 60 years, and in over 100 countries across six continents. ACG produces integrated solutions for capsules, film and foil barriers, engineering equipment, and inspection systems – all fully complying with international regulatory requirements.

For communication queries, contact the ACG media relations management team at

tanya.grover@acg-world.com

madhurima.chakraborty@acg-world.com

Pharma companies can achieve up to 99.9% defect detection accuracy thanks to the integration of deep learning models and secure, cloud-based technology. A dedicated team will support customers throughout the machine's life cycle.

Piombino Dese (PD), Italy – February 23, 2021 – Stevanato Group, a leading global provider of integrated containment and delivery solutions to the biopharmaceutical and life sciences industries, has launched an Artificial Intelligence platform, based on Deep Learning (DL) models, that leverages the benefits of human-like decision-making in automatic visual inspection equipment. The platform allows pharma companies to overcome the traditional trade-off between detection rate and false rejection rate, ensuring robust and replicable results. False rejects can be reduced tenfold, and the detection rate can be improved, yielding up to 99.9% accuracy, both for particle inspection and cosmetic defects detection.

Deep Learning is particularly beneficial when applied to difficult-to-inspect and high-value biotech drugs, as it allows pharma companies to achieve higher productivity while preserving drug integrity. Drugs in the form of suspensions or lyophilized cakes frequently challenge available vision tools, causing misinterpretations of supposed defects. Traditional systems can, for instance, misclassify cosmetic defects or air bubbles as particles. Artificial Intelligence mitigates misclassification and reduces costly re-inspection.

Thanks to its partnership with Microsoft and the adoption of Microsoft Azure platform, Machine Learning and AI features, Stevanato Group intends to deliver "smart" equipment compliant with strict pharmaceutical data management and security requirements, while improving inspection performance and reducing costs related to production reparametrization. The certified cloud-based platform is compliant with U.S. CFR 21 Part 11 and EU GMP Annex 11, meets data integrity needs, and offers advanced monitoring tools such as heat maps and confusion matrix for model performance evaluation.

Incorporating new technologies can be challenging for pharma companies, as it usually requires them to adapt internal processes and invest time and resources. The combination of the latest digital developments and a qualified team of vision and AI engineers bring a dedicated and accurate data analysis service with continuous support for tasks from image collection to model validation.

Raffaele Pace, Engineering Vice President of Operations at Stevanato Group said: "We are glad to provide our customers with inspection machines equipped with the latest AI technology, which are able to substantially increase defect detection accuracy even with the most challenging drugs. Choosing Microsoft Azure as our technology platform allows us to offer a proven solution while delivering the highest standards in terms of data security. Thanks to our skilled visual inspection engineers and experts in big data analysis, we can support clients from the implementation of Artificial Intelligence to ongoing support during operations."

Key features of the new Artificial Intelligence platform include:

Cloud-based: Data remains online and therefore perpetually available. The certified cloud-based platform that stores images and data can work with any cloud-based system and allows operators to manage images even if they are stored in the server.

Security: Compliant with U.S. CFR 21 Part 11 and EU GMP Annex 11, the platform enables data sharing in a completely safe environment. Further, multifactor authentication and encrypted communication ensure complete access control and data security.

Assistance: Continuous support is available for all platform capabilities throughout the process, assisting pharma companies with a variety of tasks including a labeling assistant tool to optimize timing for classification and new recipe development.

Monitoring: The platform features a wide range of statistics and visualizations (heat maps, confusion matrix, etc.) for model performance evaluation. Pharma companies can track and monitor all processes through real-time reports.

--------------------

ENDS

About Stevanato Group

Founded in 1949, Stevanato Group is one of the world's largest providers of integrated containment and delivery solutions for the biopharmaceutical industry. From the beginning, the Group has developed its own glass forming technology to ensure quality of the highest standards. The Group includes a wide range of skills dedicated to serving the biopharmaceutical and diagnostic industry. It offers glass containers with its historic Ompi brand, plastic components for diagnostics and medical devices, contract manufacturing services for drug delivery systems, up to inspection, assembly and packaging machines. The Group also provides analytical services and tests that study the interaction between container and drug and integration into delivery systems, supporting the drug development process. By bringing together several skills under the same entity, Stevanato Group is able to offer unique solutions to companies by reducing the time to market and the overall cost.

For more information, please visit www.stevanatogroup.com.

Press contacts:

Christopher Dale,

Director of PR and Communications at Turchette,

Considered by many as one of the ‘next big things’ in science-based beauty care, epigenetics studies our lifestyles’

The move into China is part of Quadpack’s 2020-2025 business strategy, which sets out growth plans in each of its key

“Positive-impact packaging is a long-term journey that aims to better inform our clients,” says Lyne Hélène Bouchard,

The project consists of an HK-S cartoner for packing biscuits and a subsequent case packer for forming packs in a wr