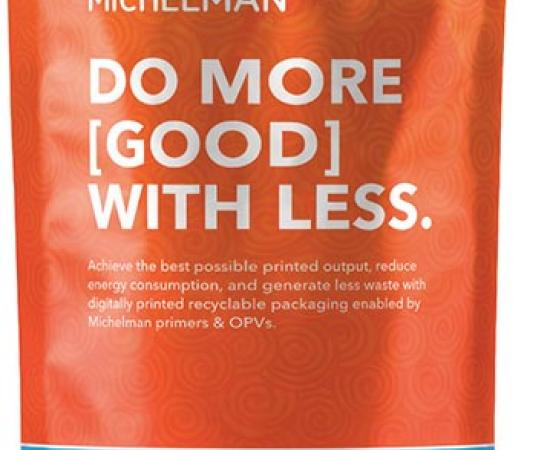

Hubergroup Redefines Cold Foil Printing with Next-Generation Silver and Gold Adhesives for FCM Applications

hubergroup is setting a new industry benchmark with its Cold Foil Silver and Cold Foil Gold adhesives, an innovative advancement designed for Food Contact Material (FCM) applications. These cutting-edge solutions offer unparalleled brilliance, safety, and efficiency, catering to the demanding needs of confectionery, chocolate, tobacco, and hygiene packaging.