- Today is:

Breaking news

Innovations

Stay informed. Our latest innovations.

Welcome to the Packaging Innovations page at Packaging Connections!

Here, we showcase the latest advancements in the packaging industry, reporting on innovative solutions that push the boundaries of what packaging can achieve. Our goal is to provide a platform for sharing cutting-edge packaging innovations, and our reporting is completely free of cost.

Submit Your Innovations

Have a packaging innovation you want to share with the world? We invite you to send us your innovations, including pictures, a detailed description, and your contact details. We are always on the lookout for groundbreaking ideas and would be happy to consider them for publication.

Promote Your Innovations

For those looking to promote their innovations more broadly, our business promotion services can help. We offer various options to get your innovation in front of the right audience, enhancing visibility and impact.

How to Submit Your Innovation

To submit your innovation for consideration, please send the following information to info@packagingconnections.com:

- Innovation pictures

- Detailed description

- Contact details

Our team will review your submission and get in touch with you for the next steps.

Contact Us

For any questions or additional information, feel free to reach out to us at info@packagingconnections.com. We look forward to discovering and sharing your innovative packaging solutions with our global audience.

Share Your News with Our Community

Are you a brand, supplier, or professional? Submit your Innovation and get featured on PackagingConnections.

Explore the Latest Innovations

Browse through our collection of the latest packaging innovations to get inspired and stay ahead of the curve. From sustainable materials to smart packaging solutions, our featured innovations represent the future of packaging.

From thermoforming and film extrusion to recycling and advanced coating processes, vacuum technology plays a pivotal role in enhancing both quality…

The new, electrically driven pallet labeller features a suite of smart technological enhancements that allow for safer operation and improved…

In a major leap towards decarbonizing the specialty glass industry, SCHOTT has officially begun construction of an electric glass melting tank that…

The open house, held at Bobst UK & Ireland’s Redditch headquarters on 17 June, provided actionable strategies for reducing operational costs,…

In a market where visual appeal and sustainability drive consumer choices, Lacerta Group has introduced an innovation that turns conventional…

In today’s market, packaging isn’t just about safeguarding products—it’s about telling a story and creating meaningful impact. At Pack Expo 2024, a…

In a compelling blend of design, safety, and sustainability, Amcor has unveiled its newest innovation in closure technology the Hector Child…

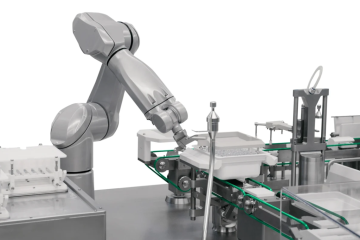

In a major stride toward next-generation pharmaceutical production, Syntegon has launched its revolutionary SynTiso line concept a state-of-the-art…

UFlex, India’s largest multinational flexible packaging and solutions company, has been granted an Indian patent (No. 567989) for its latest…

In a bold move that redefines packaging possibilities for the beauty industry, UFlex’s FlexiTubes division is all set to showcase its trailblazing…

Pagination

- First page

- Previous page

- …

- 6

- 7

- 8

- 9

- 10

- …

- Next page

- Last page