Businesses selling on Amazon Marketplace can now use this ready to go, pre-certified Bag-in-Box design avoiding the need to go through costly and time-consuming testing at a specialised ISTA certified laboratory to gain FFP certification.

Don't miss out on the latest updates! Sign up for our Namaste Packaging newsletter and join our community of over 100,000 packaging professionals. Get the latest news, trends, and innovations delivered straight to your inbox.

Are you a brand, supplier, or professional? Submit your news and get featured on PackagingConnections.

Businesses selling on Amazon Marketplace can now use this ready to go, pre-certified Bag-in-Box design avoiding the need to go through costly and time-consuming testing at a specialised ISTA certified laboratory to gain FFP certification.

HEINZ, maker of the world’s favorite ketchup and beloved condiments, is teaming up with Pulpex to develop a paper-based, renewable and recyclable bottle made from 100 percent sustainably sourced wood pulp. Innovating its iconic ketchup bottle, HEINZ is the first sauce brand to test the potential of Pulpex’s sustainable paper bottle packaging for its range of world-famous condiments.

Arctic Glacier’s shift to 51% recycled content packaging represents a 46% reduction in global warming potential impacts compared to the industry standard generic polyfilm. “We are thrilled to pioneer sustainable packaging for the ice industry. Supporting a circular economy with recycled content packaging is an important aspect of our forward-looking ESG strategy focused on creating a greener supply chain and supporting safer work environments through ethical business practices,” said Richard Wyckoff, CEO and President of Arctic Glacier, LLC.

McDonald's circular clear cups sourced from equal parts recycled and biobased materials is available in 28 select restaurants in Savannah, Georgia. When we say “circular,” we’re referring to the cup’s potential lifespan. The cups are sourced from recycled material, and our goal is that they can be recycled to create more material that could be used to make other items. It’s a way of doing things that can help keep plastic in use and out of landfills.

The cups will look and feel the same.

Today, in their Helsinki-based roastery, Meira recycles coffee waste into biogas and will attain CO2 emission decreases of around 77 tonnes yearly. The group has actually increased its waste recycling rate to reach 80% and its goal is to halve our greenhouse gas emissions by 2022.

Development is a vital component of this effort and business has actually just launched Vallilan Paahtimo, a new range that puts sustainability in the spotlight. The coffee is sustainably grown, single origin and is available in an aluminium-free item packaging.

Product innovation is becoming important

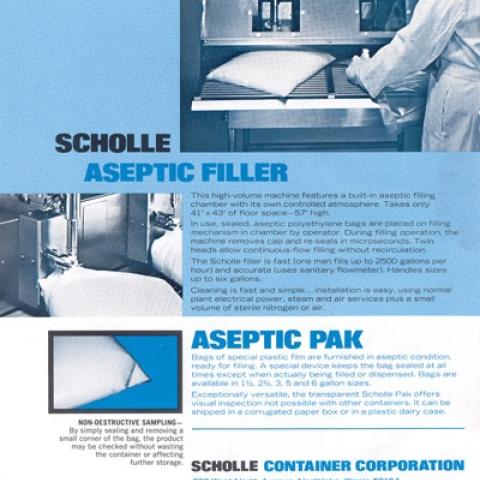

The aseptic packaging process is used for various food products and beverages, including milk, soup, tomatoes, pudding and several others. It’s also used in the pharmaceutical industry to ensure that medications aren’t polluted with harmful bacteria.

Aseptic packaging materials

Several materials are layered together to provide the level of protection required for aseptic packaging standards, including:

Scholle IPN invented the bag-in-box and revolutionized the way we package goods. Since then, we have continued to find innovative and game-changing ways to utilize packaging technology to transport food safely while reducing our environmental impact.

To address the growing need for a dependable and sustainable shipping container for biologics, Liviri created its newest innovation in cold-chain shippers: Bio