Induction sealing has become a critical packaging technology across food, beverage, pharmaceutical, cosmetic, and chemical industries. As brands focus on product safety, shelf life extension, and regulatory compliance, induction sealing offers a reliable, scalable, and tamper-evident solution. This blog explores what induction sealing is, how it works, its benefits, applications, and key considerations when choosing an induction sealing system.

What Is Induction Sealing?

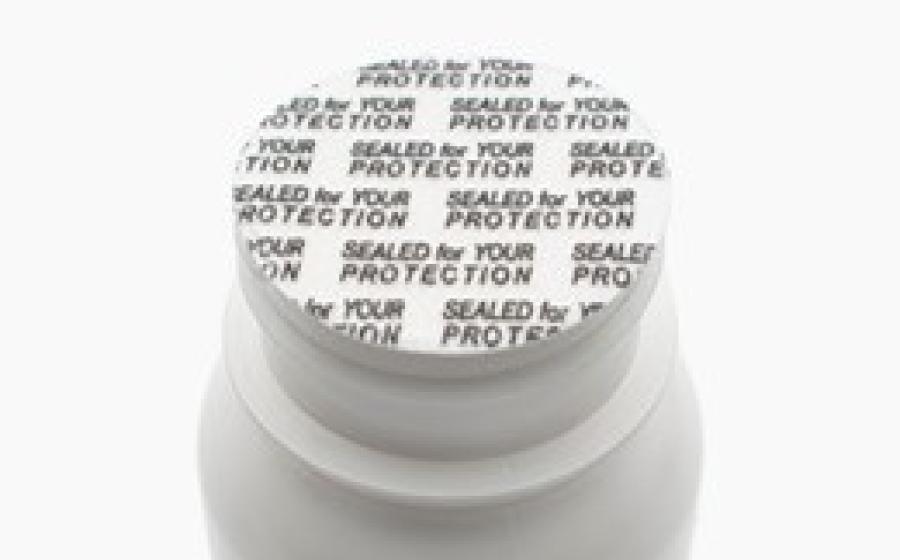

Induction sealing is a non-contact sealing process used to hermetically seal containers using an aluminum foil seal. The seal is bonded to the container’s rim using electromagnetic induction, creating an airtight and leak-proof closure.

The induction seal is typically placed inside the cap and consists of:

• A heat-sealable polymer layer

• Aluminum foil

• Backing material (often pulpboard or foam)

Once sealed, the foil must be peeled or punctured to access the product, making it an effective tamper-evident packaging solution.

How Does Induction Sealing Work?

The induction sealing process involves four main steps:

1. Cap Application

The cap with the induction liner is applied to the filled container.

2. Electromagnetic Induction

The container passes under an induction sealing head, which emits a high-frequency electromagnetic field.

3. Heat Generation

The aluminum foil layer heats up due to eddy currents, melting the polymer layer.

4. Seal Formation

The molten polymer bonds to the container lip. Once cooled, it forms a strong hermetic seal.

Because the process is contactless, it is highly suitable for high-speed production lines.

Key Benefits of Induction Sealing

1. Tamper Evidence and Consumer Safety

Induction seals provide visible tamper evidence, helping brands comply with food safety and pharmaceutical packaging regulations while building consumer trust.

2. Leak-Proof Packaging

Induction sealing prevents leaks during transportation, handling, and storage—especially important for liquids, oils, syrups, and chemicals.

3. Extended Shelf Life

The hermetic seal protects products from moisture, oxygen, and contaminants, helping maintain freshness and efficacy.

4. Compatibility with Automation

Induction sealing machines integrate easily into automated packaging lines, supporting high throughput and consistent seal quality.

5. Sustainability Advantages

By reducing product spoilage, recalls, and leakage-related waste, induction sealing indirectly supports sustainable packaging goals.

Applications of Induction Sealing

Induction sealing is widely used across industries, including:

• Food & Beverage: Sauces, dairy, spices, honey, nutritional supplements

• Pharmaceuticals: Tablets, syrups, OTC medicines, vitamins

• Cosmetics & Personal Care: Lotions, creams, shampoos

• Chemicals & Agrochemicals: Lubricants, pesticides, cleaning agents

Its versatility makes it suitable for containers made of HDPE, PET, PP, PVC, and glass.

Types of Induction Seals

• One-Piece Induction Seals: Foil seal remains on the container after cap removal

• Two-Piece Induction Seals: Foil bonds to the container while backing stays in the cap

• Vented Induction Seals: Allow gas release while maintaining leak resistance

• Printed Induction Seals: Enable branding, instructions, or authentication features

Choosing the Right Induction Sealing System

When selecting an induction sealing solution, consider the following factors:

• Container material and neck finish

• Product type (liquid, powder, solid)

• Line speed and production volume

• Regulatory requirements (FDA, EU, pharma standards)

• Seal strength and peelability requirements

Testing and validation are essential to ensure optimal seal integrity and performance.

Future Trends in Induction Sealing

Advancements in induction sealing technology include:

• Smart seal verification systems

• Recyclable and mono-material induction liners

• Improved energy-efficient sealing heads

• Enhanced tamper-evidence and anti-counterfeiting features

As packaging regulations tighten and sustainability expectations rise, induction sealing will continue to play a pivotal role in modern packaging design.

Conclusion

Induction sealing is more than just a closure technology—it is a safeguard for product quality, consumer safety, and brand reputation. By delivering tamper evidence, leak prevention, and extended shelf life, induction sealing remains an essential component of high-performance packaging systems across industries.