- Today is:

Breaking news

Innovations

Stay informed. Our latest innovations.

Welcome to the Packaging Innovations page at Packaging Connections!

Here, we showcase the latest advancements in the packaging industry, reporting on innovative solutions that push the boundaries of what packaging can achieve. Our goal is to provide a platform for sharing cutting-edge packaging innovations, and our reporting is completely free of cost.

Submit Your Innovations

Have a packaging innovation you want to share with the world? We invite you to send us your innovations, including pictures, a detailed description, and your contact details. We are always on the lookout for groundbreaking ideas and would be happy to consider them for publication.

Promote Your Innovations

For those looking to promote their innovations more broadly, our business promotion services can help. We offer various options to get your innovation in front of the right audience, enhancing visibility and impact.

How to Submit Your Innovation

To submit your innovation for consideration, please send the following information to info@packagingconnections.com:

- Innovation pictures

- Detailed description

- Contact details

Our team will review your submission and get in touch with you for the next steps.

Contact Us

For any questions or additional information, feel free to reach out to us at info@packagingconnections.com. We look forward to discovering and sharing your innovative packaging solutions with our global audience.

Share Your News with Our Community

Are you a brand, supplier, or professional? Submit your Innovation and get featured on PackagingConnections.

Explore the Latest Innovations

Browse through our collection of the latest packaging innovations to get inspired and stay ahead of the curve. From sustainable materials to smart packaging solutions, our featured innovations represent the future of packaging.

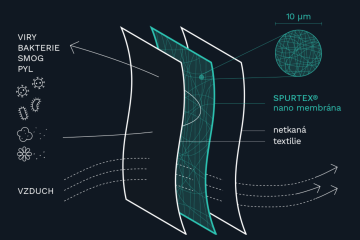

The unique nanostructured filter material SPURTEX® is developed and produced by the Zlín company SPUR, a leading Czech expert in nanotechnology.…

Their latest product development: The articc.m6-2390-150kg (art n°: AT_00016)!

Due to its rigid, compact, and closed design, the robot is perfectly…

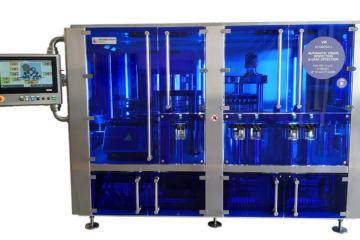

Antares Vision Group is a technological partner of excellence in digitalization and innovation for companies and institutions with a complete…

AluSense produces mono-material capsules. They are made from 100% aluminum and have no paper or silicone ring. Their innovative capsules guarantee…

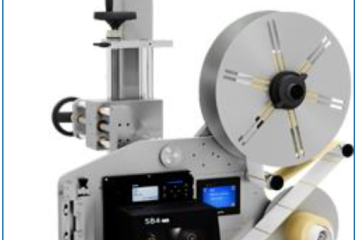

ALcode is the name that distinguishes, within the ALtech range, the print application systems of self-adhesive labels, which in various…

A 3D-printed device developed by Curiteva incorporating PEEK filament from Evonik was surgically implanted last week in Allentown, PA. It’s the first…

The Valencian startup has its sights set on the current BIO market and, given the new need to improve the impact resistance of base PLA, has decided…

Available in the US, the device, which was developed with Silgan Dispensing’s bioequivalence (BE) program, is adaptable to specific…

Actipack new model, named YOGO 120 ml, is proposing the transparency and the standard dimensions of yogurt cups from the market.

The advantages…

Stelda's case-sealing solution makes shipper cartons stronger, more secure, and at the same time, sustainable. Our patented 'tamper evident sealing'…

Pagination

- First page

- Previous page

- …

- 30

- 31

- 32

- 33

- 34

- …

- Next page

- Last page