Revolutionizing Plastic Labeling: Polymer Fusion Technology Offers Unmatched Durability and Eco-Friendly Solutions

Since 1983, a company has been driving innovation in the world of labeling, unveiling a breakthrough solution aimed at tackling the longstanding challenges faced by traditional labeling methods. Recognizing the critical role labels play in branding, safety, and tracking, the company has developed Polymer Fusion Label Technology, a game-changing approach that promises to eliminate the frustrations of peeling, fading, and falling labels on plastic products.

The Problem with Traditional Labeling

Traditional labeling methods have long been inadequate for polyolefin thermoplastics, which are known for their low surface energy and non-polar nature. These characteristics make it nearly impossible for standard adhesives to bond effectively, leading to premature label failure in the face of exposure to weather, chemicals, and general wear and tear. The result is costly rework, production slowdowns, and a damaged brand reputation for manufacturers, while end users face frustration, non-compliance, and a loss of product integrity.

Enter Polymer Fusion Technology

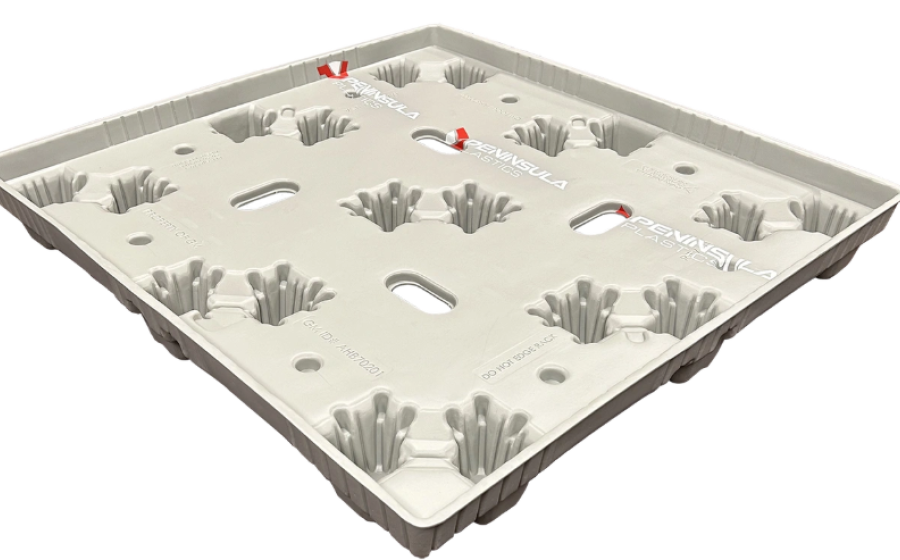

Polymer Fusion Label Technology, however, offers a permanent solution that completely overcomes these issues. Rather than relying on adhesives, this innovative process fuses the label directly into the plastic during the molding process. This integration creates a seamless bond, ensuring that labels stay intact and legible for the entire life of the product, no matter the environmental conditions.

Key Benefits of Polymer Fusion Labels:

- Lifetime Durability: Resistant to UV exposure, chemicals, and extreme temperatures, these labels remain intact throughout the product’s lifespan, reducing the need for frequent replacements.

- Cost Efficiency: While the upfront cost may be higher, the longevity of the labels eliminates the need for costly rework or replacements, resulting in significant long-term savings.

- Enhanced Branding and Compliance: With clear, legible labels that remain intact, brands can maintain their identity and meet stringent regulatory requirements, ensuring compliance throughout the product lifecycle.

- Customization and Flexibility: These labels are fully customizable, allowing for logos, safety information, and regulatory markings without compromising on durability.

- Environmental Benefits: Polymer Fusion Labels are fully recyclable and won’t peel or degrade, supporting sustainability goals while reducing waste and environmental contamination.

A Sustainable Solution for the Future

In addition to their durability, these labels are fully compatible with polyolefin thermoplastics, which are recyclable up to ten times. Traditional labels, made from paper, ink, adhesives, and coatings, often have to be removed before recycling, creating additional waste and downtime. Polymer Fusion, however, eliminates this step, making it easier to recycle products without the need for label removal, resulting in a cleaner process with zero waste.

Polymer Fusion represents a leap forward in labeling technology—one that addresses the long-standing problems of traditional labels while offering a more sustainable and efficient solution for manufacturers and consumers alike. The new technology not only enhances the longevity of products but also supports environmental efforts by reducing waste and simplifying recycling processes.

With Polymer Fusion Label Technology, the future of labeling is permanent, reliable, and eco-friendly, setting a new standard for industries that require durability, compliance, and sustainability.