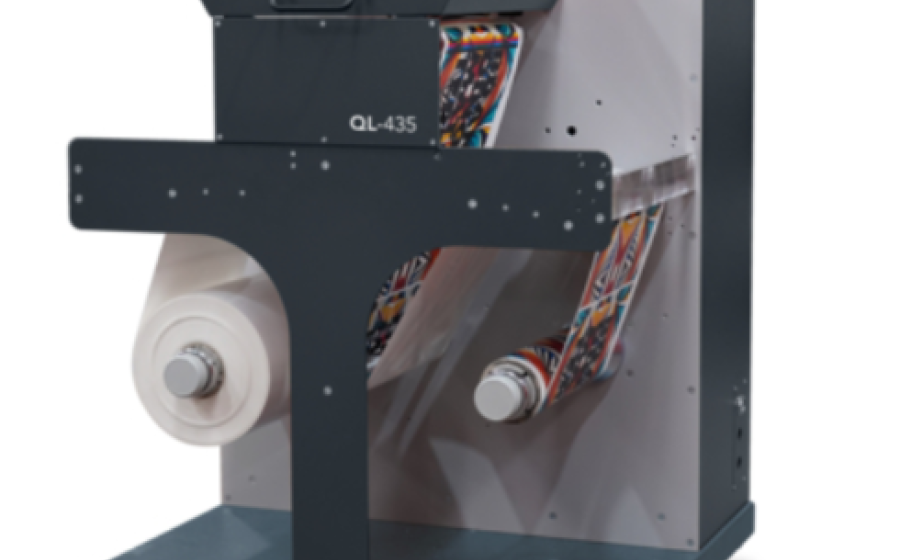

At the FESPA Global Print Expo 2025 in Berlin, AstroNova, Inc. (Nasdaq: ALOT) introduced a suite of high-performance digital printing solutions, marking a significant advancement in the product identification segment. The launch includes the QuickLabel® QL-425 and QL-435 professional label presses, alongside the VP-800 direct-to-package printer, designed to meet the evolving needs of label converters and print service providers (PSPs) focusing on medium-volume runs.

- Today is: