Blister packaging and strip packaging are two popular forms of the primary packaging system.

However, it is difficult to differentiate between blister packaging and strip packaging. Besides, the difference between a strip pack and a blister pack you may find out from here.

Blister packaging |  Strip packaging |

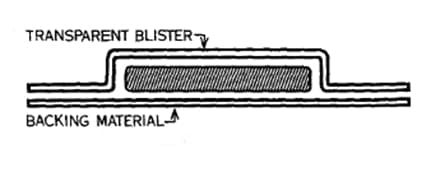

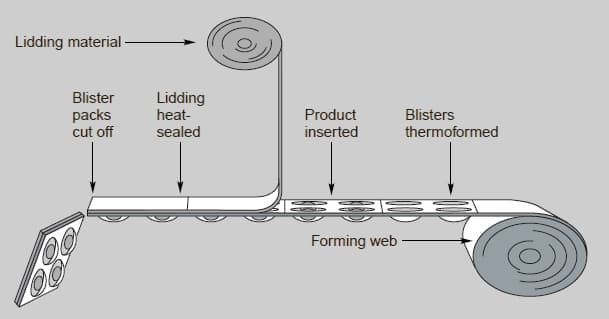

| Unit-dose packaging in which a semi-rigid blister/ cavity previously formed is filled with product and lidded with a heat-sealable backing material | Unit dose packaging in which a pharmaceutical product is enclosed between two webs of heat-sealable flexible film |

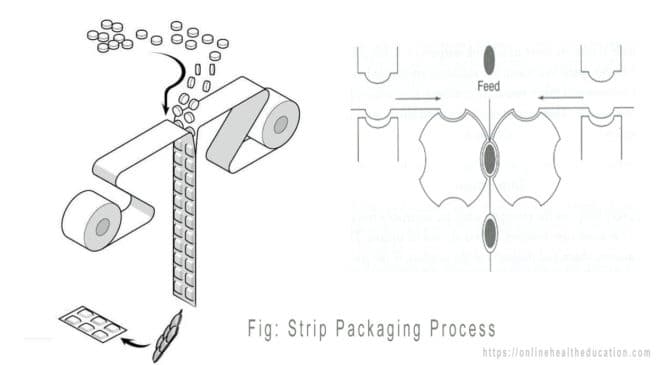

| Blister/ cavity/pocket is formed either a thermoforming or cold forming process | Product is enclosed between two webs of heat-sealable flexible film through a heated reciprocating platen or a heated crimp roller. |

| Blister packs are made through a form-fill-seal method | Strip packs are formed around the tablet at a time when it is dropped to the sealing area |

| Blister packs are usually produced at higher speeds than Strip. | Strip packs are usually produced at lower speeds than the blister. |

| Blister Packs have less possibility of wrinkling while sealing. | The formed strip pockets are too tight, thus, wrinkling of the seal area or perforation of the pocket periphery may occur. |

| Provide more mechanical protection | Risk of product damage during handling /prone to mechanical damage. |

| More air entrapped onto blister | Less air entrapped, so provide more protection from air molecules and moisture. |

| Less child resistance | More child resistance |

| Easy to use | Strip pack is not usable by the elderly and patients with arthritic fingers. |

| Blister packaging offers good display advantage. So, blister packaging helps customers to see pharmaceutical products, further aiding in their buying decision | Strip packaging does not offer good display advantage |

| Blister pack occupies less space | Strip pack occupies more space |

| A product is displaced from a Blister pack by pushing or peeling | A product is displaced from a strip pack by tearing |

| In Blister packaging, blister/cavities are formed either thermoformed or cold-formed process. | In strip packaging, thermoformed or cold-formed cavities are absent. |

Two basic types of pharmaceutical blister packaging exist. • Thermoform blister packaging • Cold stretching blister packaging | Strip packaging has no such type. |

| Blister packs use as a primary pack for a range of pharmaceutical products such as tablet, pill, capsule, suppository, vial, and ampule | Strip packaging is an alternative primary packaging system that used to pack especially capsule, also tablet |

|