display_title

SUSTAPEEK 3D printer build surface for fused deposition modelling

Categories

Short Description

Save time and resources: High adhesion without surface treatment

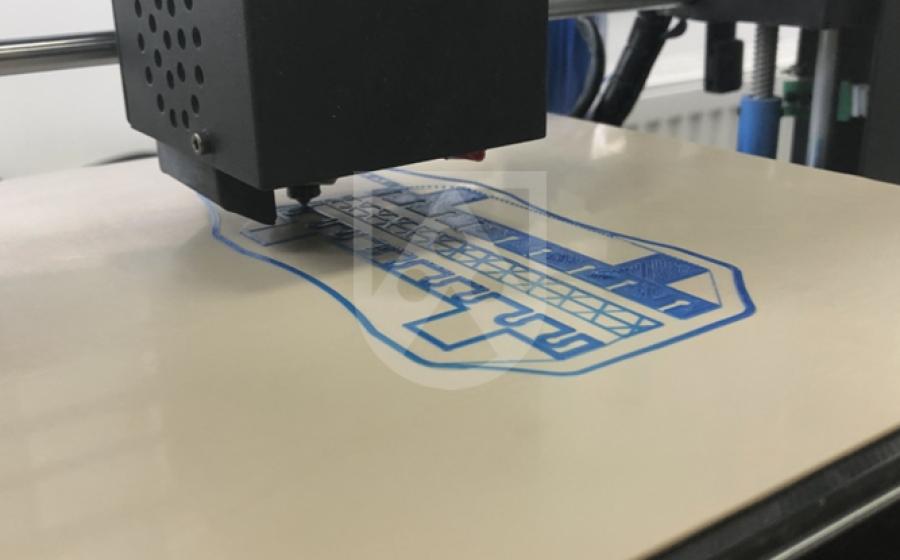

Röchling Sustaplast SE & Co KG of Lahnstein, Germany, now offers a 3D printer build surface made of the high-performance plastic SUSTAPEEK especially for fused deposition modelling (FDM). The material has a very strong adhesion to the print object during the material application in the printing process. The complicated surface processing required for a conventional 3D printer build surface is not needed here. 3D printers thus save time and money. The SUSTAPEEK 3D printer build surface is available in very low thicknesses from 1 mm up to 4 mm. They enable particularly good heat transfer. Components can thus be manufactured quickly and reliably.

Röchling Sustaplast SE & Co KG of Lahnstein, Germany, now offers a 3D printer build surface made of the high-performance plastic SUSTAPEEK especially for fused deposition modelling (FDM). The material has a very strong adhesion to the print object during the material application in the printing process. The complicated surface processing required for a conventional 3D printer build surface is not needed here. 3D printers thus save time and money. The SUSTAPEEK 3D printer build surface is available in very low thicknesses from 1 mm up to 4 mm. They enable particularly good heat transfer. Components can thus be manufactured quickly and reliably.