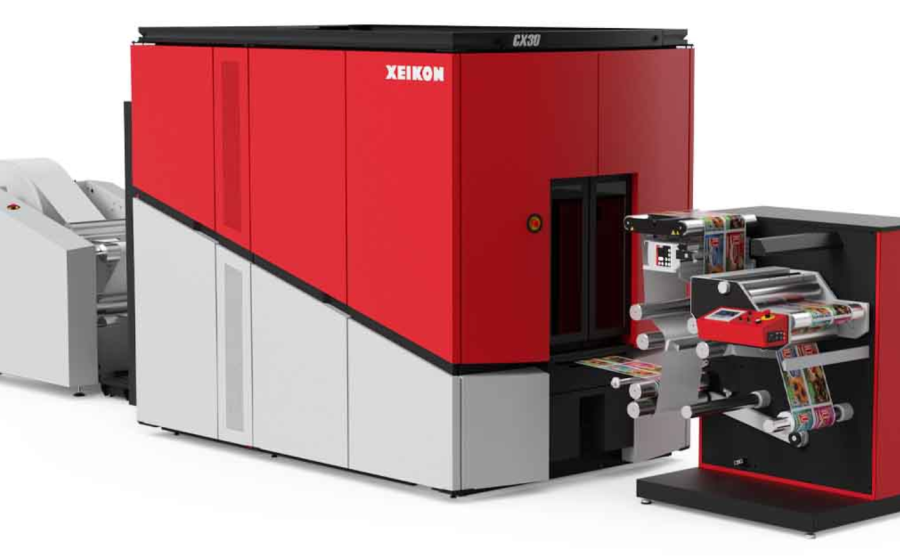

Lotus Labels has placed an order for the new Xeikon CX30 digital press, a next-generation toner-based print engine designed for high-quality self-adhesive labels and capable of handling carton board up to 0.55mm thick. The investment replaces a ten-year-old Xeikon machine and aligns with the company’s commitment to sustainability, efficiency, and market adaptability.

Andreas Schillinger, Managing Director at Lotus Labels, commented:

“The label industry continues to evolve rapidly. While our previous Xeikon press still delivered award-winning results—including earning us ‘Label Printer of the Year’—significant advancements in speed and toner technology prompted us to upgrade. The CX30 ensures we stay ahead, providing our clients with top-tier, environmentally friendly packaging solutions.”

The Xeikon CX30 leverages the company's latest Eco toner, offering color-calibrated print across a broad substrate range while maintaining low waste levels. The toner is odorless, migration-free, and vegan, making it suitable for direct food contact—a crucial factor for many of Lotus Labels’ premium customers.

Expanding Capabilities: From Labels to Cartons

The new press enables Lotus Labels to extend its production into digitally printed carton packaging, capitalizing on the ability to print both labels and cartons on the same press—ensuring perfect color matching and streamlined production for brand consistency.

“We believe dry-toner technology is best suited for digital carton work,” Schillinger added. “It allows us to handle a wide range of substrates and board thicknesses, something that other digital technologies struggle with.”

Technology and Sustainability at the Forefront

Equipped with five dry-toner stations (CMYK + opaque white), the CX30 prints at 1200 dpi and supports unique features like opaque underlay/overlay, full-color variable data printing, and seamless cloud connectivity for streamlined workflows.

Xeikon’s Eco toner technology reflects increasing market demand for sustainable print solutions. Produced with up to 60% recycled content—including PET bottles—and manufactured using 100% green electricity, these toners are also de-inkable from both paper and film substrates, facilitating recycling and reducing environmental impact.

Complementing Flexo Capabilities

Lotus Labels will continue to operate one flexo press alongside the new digital unit.

“The work mix has evolved, and while digital dominates short-run jobs, flexo still plays a vital role in our offering,” said Schillinger. “Back in 2014, we ran four flexo presses. The shift to digital was essential to stay competitive.”