As the global coffee industry moves toward more sustainable packaging, Syntegon is stepping up with an innovative solution designed to meet both performance and recyclability standards. The company’s new PMX 4001 vertical bagger enables coffee roasters to transition seamlessly to eco-friendly packaging without compromising on quality, aroma protection, or shelf life.

Designed for the Circular Future

The European Union’s Packaging & Packaging Waste Regulation (PPWR) will prohibit circulation of multi-layered laminates with less than 70% recyclability by 2030. Anticipating this shift, Syntegon developed the PMX 4001 with sustainability at its core.

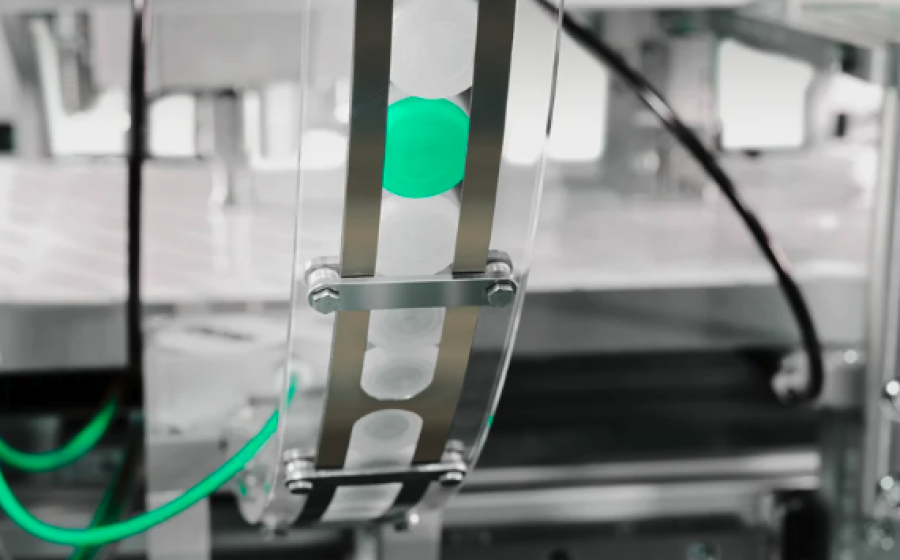

This high-performance bagger efficiently processes a wide range of recyclable mono-materials as well as traditional composites, giving manufacturers flexibility during their transition phase. Based on Syntegon’s modular PMX platform, the PMX 4001 can fill up to 65 gable-top block-bottom bags per minute, offering multiple sealing options for varied packaging needs.

Protecting Aroma and Quality

To maintain coffee’s freshness and aroma, the PMX 4001 integrates an ultrasonic valve applicator for recyclable VIS 10F degassing valves, recently certified as recyclable in Europe by the cyclos-HTP institute.

A low drop height during filling minimizes residual oxygen, ensuring optimal aroma protection and extended shelf life. Combined with precise sealing technology, the system guarantees premium shelf appearance — a key factor influencing consumer purchase decisions.

Compact, Intelligent, and Efficient

Beyond sustainability, Syntegon designed the PMX 4001 for maximum efficiency in minimal space. With a footprint of just 2.6 x 2.1 meters and a height of 2.2 meters, it delivers high output and operational reliability even in compact production environments.

The machine is also equipped with Synexio Empower, Syntegon’s digital monitoring solution, which tracks process parameters, machine performance, and energy consumption in real time. Predictive maintenance functions help minimize downtime and extend machine life, ensuring long-term operational stability.

For greater production flexibility, the PMX 4001 can operate as a stand-alone system or integrate seamlessly into a turnkey packaging line, including secondary packaging with Syntegon’s Elematic case packer—available in wrap-around, side, or top-loading configurations.

A Sustainable Step Forward for Coffee Roasters

With the PMX 4001, Syntegon offers coffee producers a future-proof packaging solution that aligns with evolving sustainability regulations while maintaining the highest quality standards for coffee preservation and presentation.

By combining innovative engineering, digital intelligence, and sustainable design, Syntegon is setting a new benchmark for next-generation coffee packaging technology—helping manufacturers stay competitive in a greener, more circular economy.