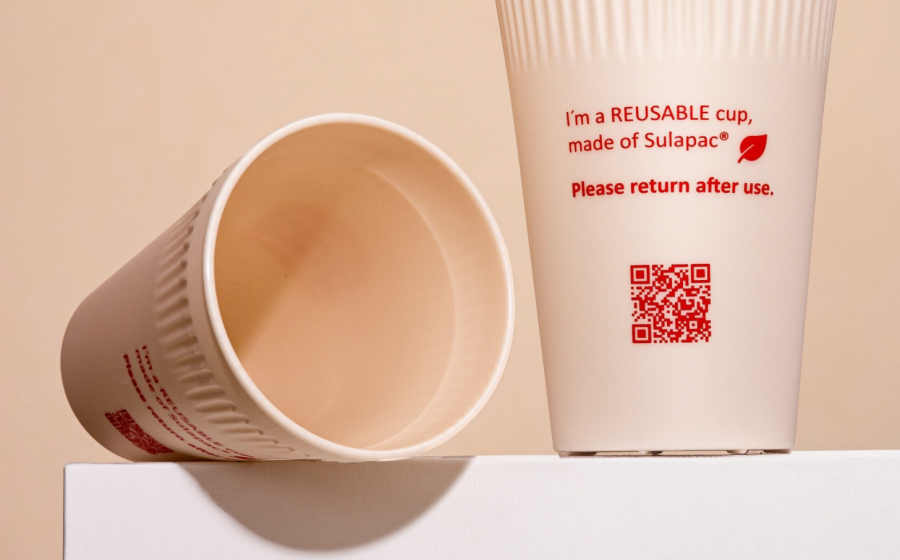

TripleW, a Belgian leader in circular biochemistry, and Sulapac, the Finnish pioneer of sustainable plastic alternatives, have joined forces to demonstrate what true circularity looks like. Their latest closed-loop pilot proves that reusable cups made from Sulapac Solid, a 100% biobased, biodegradable, and highly durable material, can be chemically recycled at a commercial scale.

This milestone not only eliminates the need for fossil-based materials but also unlocks long-term cost advantages and aligns seamlessly with the EU’s ambitious circularity and bioeconomy goals.

“This is an important milestone for the EU’s Bioeconomy Strategy. We eliminate single-use plastics, improve resource efficiency, and offer clients a truly circular solution,”

Tal Shapira, CEO, TripleW

Material Innovation That Behaves Like the Future

Sulapac Solid is engineered for repeated use while maintaining a premium, ceramic-like look and feel. Dishwasher safe and highly durable, it fits directly into existing plastic production processes and is designed for high-stress environments from aviation and cruise hospitality to quick-service restaurants.

This positions Sulapac Solid as a scalable, high-performance replacement for oil-based reusable plastics, without compromising quality or functionality.

Breakdown, Rebuild, Repeat — The Power of Polymer-to-Polymer Recycling

TripleW’s advanced recycling platform brings an additional layer of innovation. In the pilot, used Sulapac Solid cups were:

- Collected

- Ground

- Hydrolyzed into their base components , including lactic acid, the fundamental building block of PLA

This lactic acid can then be used in cosmetics, pharmaceuticals, or turned back into food-grade biopolymer, enabling endless circularity without degradation in quality.

“We’re proving that biobased, compostable materials like PLA-based compounds aren’t just sustainable they’re genuinely circular,”

Tal Shapira, CEO, TripleW

From Closed-Loop Demonstrator to Scalable European System

TripleW and Sulapac are now inviting organizations across hospitality, events, and passenger transport sectors to adopt this one-of-a-kind circular model. The goal is to significantly scale collection and recycling volumes in the coming years.

“This partnership shows that high-performance, sustainable materials can circulate just like traditional plastics without the environmental cost,”

Dr. Peltola, Sulapac

Beyond environmental value, the closed-loop model offers:

- Lower raw material and logistics costs

- More resilient supply chains

- Reduced regulatory burden under evolving EU packaging policies

This approach directly supports the EU Green Deal, Circular Economy Action Plan, and upcoming Packaging & Packaging Waste Regulation (PPWR) positioning Europe as a global leader in circular bioeconomy solutions.

“Circular bio-based innovations like this strengthen industrial competitiveness and deliver scalable alternatives to fossil-based packaging,”

- Tal Shapira