- Today is:

Breaking news

Press Release

Stay informed. Our latest Press Release.

Share Your News with Our Community

Are you a brand, supplier, or professional? Submit your Press Release and get featured on PackagingConnections.

Press Packagingconnections

12 February, 2026

Innovation, Quality and Enthusiasm: 75 Years of Schreiner Group Entering the 2026 Anniversary Year with Traditional Munich…

Press Packagingconnections

10 February, 2026

Rajoo Bausano Extrusion Pvt. Ltd., the global pioneer in pipe & profile extrusion lines, is set to create a commanding presence at Plastindia…

Press Packagingconnections

10 February, 2026

AGRIPOWER France, founded in 2012 in Saint-Sylvain-d‘Anjou, is an experienced supplier and operator of biogas plants in France. The company stands…

Press Packagingconnections

10 February, 2026

Compact, servo-driven system ensures precise, reliable, and GMP-compliant cartoning for bottles, blisters, and tubesELMACH, a global provider of…

Press Packagingconnections

10 February, 2026

• To showcase innovations from four of its key businesses – Cosmo Films, Cosmo Speciality Chemicals, Cosmo Plastech and Cosmo…

Press Packagingconnections

10 February, 2026

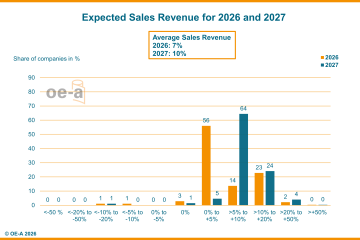

OE-A Business Climate Survey 2026 for Flexible and Printed Electronics: Growth outweighs uncertainty

Revenue growth of 7 percent expected for 2026Companies expect stronger growth in 2027: +10 percentIndustry is investing more heavilyDespite…

Bhaskar Ch

09 February, 2026

F-HSS is a co-extruded PET film featuring a specially engineered copolymer-based sealant layer. The film is heat-sealable on one side and delivers a…

Press Packagingconnections

09 February, 2026

New Delhi, February 6, 2026: UFlex Limited, India’s largest multinational flexible packaging and solutions company, has launched its latest…

Press Packagingconnections

09 February, 2026

Dry vacuum pumps from Leybold for greater operational safety and environmental protectionCologne, February 2026 – A dry vacuum offers many advantages…

Press Packagingconnections

09 February, 2026

With India mandating 20% recycled content in flexible plastic packaging by 2027, and many other “circular economy” initiatives arising around the…