Protect Your Products More With Shrink Film (POF)

Recently shrink film is significantly used to protect and ensure product quality during storing, shipping, or retailing. Therefore, POF shrink film has gradually become popular in industries to provide excellent protection.

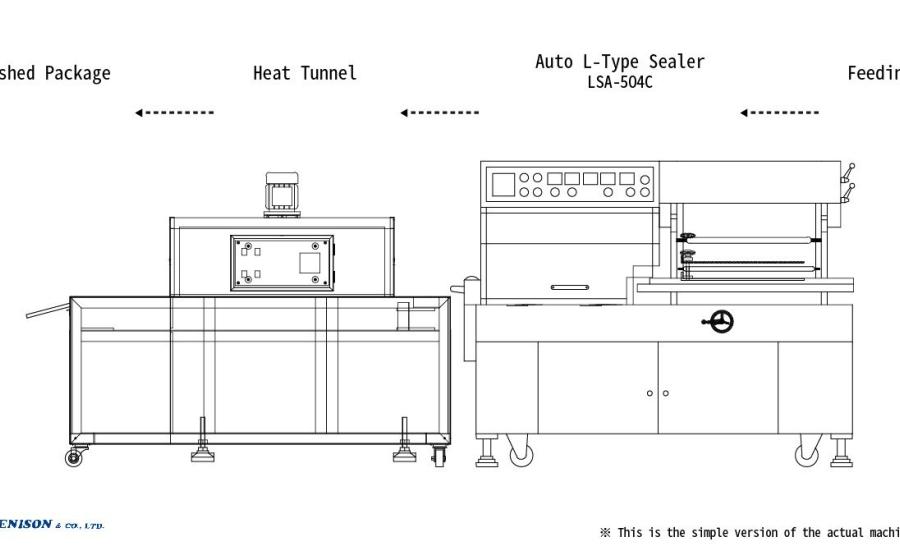

To meet high demand and consumer expectation of quality products, machine with advanced technology is needed. Benison’s L Bar Sealer LSA-504C which is connected with heat shrink tunnel AS-350 is the answer.