Activity

-

After a very successful 6th edition, the 7th edition of PharmaLytica will be held in the heartland of Pharma industry in India i.e. Mumbai from 9-11 Sep, 2020 at the Bombay Exhibition Centre in Goregaon (E). At this international trade fair, Pharmaceutical community can pick up on the latest industry trends, innovations and do business with Pharma

-

Hul to acquire vwash from glenmark pharm...

VWash was launched by Glenmark in 2013 and the brand has established itself as the market leader in the female intimate -

Glaxosmithkline consumer healthcare limi...

In addition, the Board of Directors of HUL today approved HUL acquiring the Horlicks Brand for India from GSK for a cons -

Bacteria bounce off repellant surface fo...

-

Temperature and tampering technology for...

As the world’s scientists rush to find vaccines and therapeutics to treat COVID-19, there’s another group of scientists -

Active packaging solution could disinfec...

The N95 masks are desperately needed by healthcare personnel due to the shortage of disposable masks during the COVID-19 -

Unwrapping a new opening: tetra fino® a...

-

Gogo squeez® pouch packaging with the g...

-

Resource-saving packaging for temperatur...

-

Wiping unsustainable worries away: mondi...

-

Innovative protective films for sub-zero...

The new protective films are suitable for use on both stainless steel and painted metals. -

Aptar launches invisishield™ active pa...

“We are extremely proud of our technology and the tremendous amount of work that has led to this launch. -

Old spice and secret become first major ...

As we celebrate the 50th anniversary of Earth Day this week, we’re excited to announce that Old Spice and Secret are the -

Textiles ministry extends limit for hdpe...

The Ministry of Textiles has given dilution to the maximum permissible limit i.e. -

Tethered caps: firmly attached to the bo...

The European Union published Directive 2019/904 on the reduction of the impact of certain plastic products on the enviro -

Kite packaging designed a new face visor...

Our team of 12 engineers designed concepts for the visor and a prototype was tested locally by medics last weekend to al -

Aptar announces the world’s first pack...

Plastic at the core of a new circular economy

-

Modern plastics making facemask shields ...

Shelton, Conn.-based Modern began making the shields recently and already is scaling up to production of more than 1

-

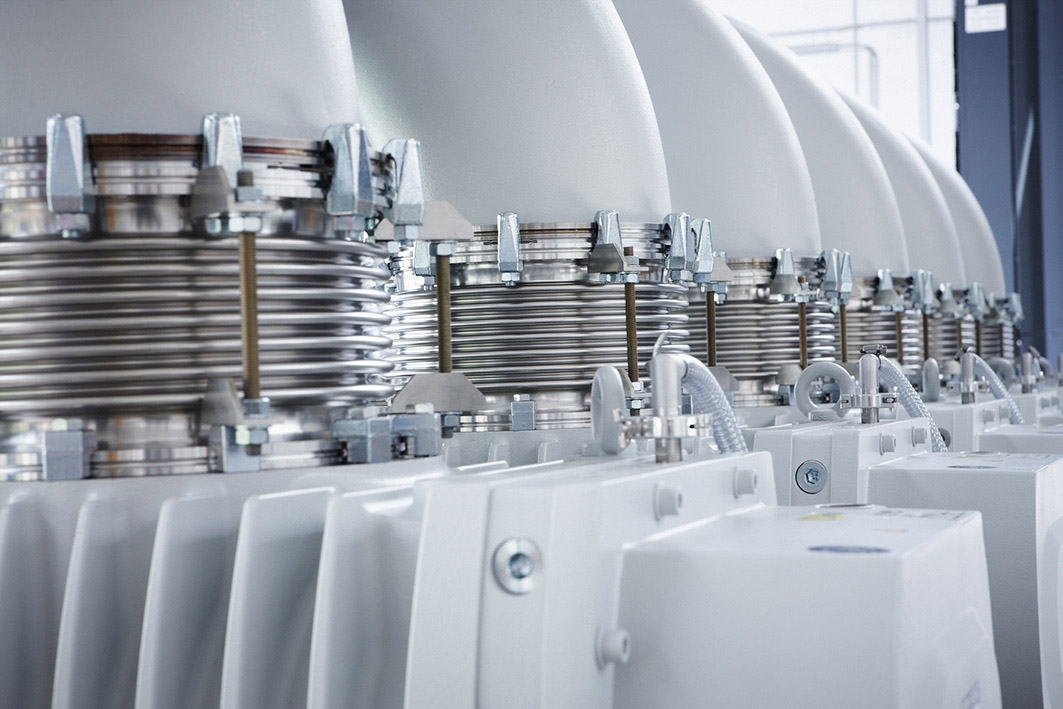

Leybold launches two vacuum calculation ...

Cologne, January 2020 – Vacuum technology specialist, Leybold, has developed two new online tools to assist customer’s pump choice and layout of complete vacuum systems: The Pump Finder and the calculation tool LEYCALC. With these new web-based tools, users can select and build their vacuum solutions online. They are designed to be used for two different use cases: The homepage https://calc.leybold.com/en/lp leads to both the Pump Finder and LEYCALC, the vacuum system calculation tool. Users with vacuum know-how can use LEYCALC to calculate the behavior and performance of vacuum systems in detail. The Pump Finder guides even beginners to suitable products by a questionnaire.

Step by step to the right offer

The Pump Finder is designed to navigate vacuum users step-by-step to find the ideal pump for their application. Throughout the selection tool, pumps can be refined by entering values for chamber size, target pressure and pipe dimensions. There are two calculation options for modelling different vacuum applications: process flow and vacuum chamber pump down. A process gas flow is a continuous gas flow where the constant pressure is conveyed. A vacuum chamber pump down is an application where the chamber is pumped/evacuated to a specific target pressure. The result is a selection of vacuum pumps that meet the customer's requirements.

Targeted product selection

LEYCALC can be used for detailed engineering of vacuum systems using the same powerful algorithms as Leybold’s application experts. The tool allows customers to calculate their vacuum systems fully independently and for complex scenarios, the experts offer their full support. "Previously, we had to adjust parameters such as chamber size, process gases, cycle times, pipe length and pressure values during the initial contact with the customer. With the help of the simulation software, the user can independently calculate configurations and get an initial idea of the vacuum performance," explains Dr. Tom Kammermeier, Global Application Manager, Industrial Vacuum. "In the past, there were often lengthy dialogues about such details," says Kammermeier. Now users can perform their calculations independently – with the result that the entire process leads to a more targeted and faster selection of the right solutions for the application. "We expect LEYCALC to improve the contact quality with our customers," summarizes Kammermeier.

Efficient communication and fast solutions

Once the user of the online tool has defined the pump’s chamber and the target pressure, LEYCALC performs the calculation of a pump down curve: The result is immediately displayed in a diagram. This shows exactly how long it takes to pump the air out of the chamber to a defined pressure and how the pressure develops over time. Alternatively, the user can calculate the pumping speed curve of a pump system. This shows which pumping speed is provided at a certain pressure. All calculation data is stored centrally and can be called up at any time and from any device by customers who have registered. Calculation results can also be shared with specialists at Leybold. This allows a detailed discussion about the respective vacuum application. Overall, the platform leads to considerably more efficient customer communication and faster solutions in complex projects. Leybold’s vacuum experts will be happy to answer any questions regarding specific calculations in a timely fashion.

Conductivity losses immediately apparent

"In addition to the chambers and pumps of a vacuum system, the different influences of pipelines are also taken into account. These include the conductance effects in all pressure ranges and flow regimes, blocking and, of course, the volume of the lines," explains Hannes Kamecke, the IT manager responsible for the online configurator. In some cases, it then becomes apparent that a pump with higher individual performance would not improve the overall vacuum performance because the reductions are caused by an incorrectly dimensioned pipeline. "However, the diagram immediately shows that the pipe diameter needs to be increased," explains Hannes Kamecke.

Further development planned

Navigation through the web-based software solution is conveniently possible on all kind of devices like tablets, smartphones. Sections in need of explanation are linked to more detailed background information on vacuum technique. In future, LEYCALC will comprise the whole Leybold product portfolio, covering also high vacuum applications. "With the publication of the new calculation tools, Leybold makes its vacuum know-how collected over decades available to its customers and thus lays the foundation for modern digital customer communication. The offer thus represents an important building block in the digital customer experience strategy of the vacuum specialist," concludes Hannes Kameck

Image

-

At pmec 2019, acg group introduces nxt s...

ACG Group, the only supplier in the world offering end-to-end manufacturing solutions for the pharmaceutical industry – is showcasing a comprehensive portfolio of next-generation production, packaging and inspection machinery. Comprising equipment solutions from two of its four business units, ACG Engineering and ACG Inspection, the NXT Series are future ready machines which will provide smart USER experience to our customers. Under the NXT series, the machines included are Protab 300 NXT, Protab 700 NXT, BMax NXT, KartonX NXT, Verishield CS18 NXT.

An acronym, USER stands for UltraHMI, StealthDesign, ExploreAR (Augmented Reality) and RevealiOT. Combined, the elevated elements, bring sweeping changes to a significant portfolio of ACG machinery including tablet presses, blister and cartoning packing equipment and serialization units for Track and Trace applications. The result is a sizable step forward in all facets of the production experience:

• UltraHMI: Aligning with the continued push for increasingly automated manufacturing solutions, ACG’s newly imagined HMI system provides seamless control of high-precision, contamination-free machines requiring minimal humanmachine interaction. Highlights include a simplified operator experience, better data visualization, decision dashboard and of course, IIoT enabled.

• StealthDesign: With a smooth, flowing style, the sleek new machine look exemplifies ACG’s commitment to versatility, maneuverability, and maximized output at a minimized footprint.

• ExploreAR: Smarter, secure, and faster, ACG’s unsurpassed Augmented Reality solutions raise the bar of process efficiency. Harnessing the potential of AR technology, ExploreAR reduces production downtime, identifies and resolves maintenance issues more quickly, and keeps manufacturing moving at a more optimized pace. Highlights include real-time monitoring, remote diagnosis and proactive service support, proactive maintenance and more realistic operator training.

• RevealiOT: ACG’s IIoT platform enables intermachine connectivity and smart manufacturing processes via easy-to-read dashboards detailing heretofore difficultto-measure KPIs. Digestible data provides actionable metrics, a quantum leap in transparency leading to predictive maintenance, improved product quality and maximized overall equipment effectiveness (OEE). The treasure trove of new information also allows for “Golden Batch” repeatability and optimized production schedules, significantly improving machine efficiency while reducing line downtime.

About ACG

ACG group is the world’s only integrated pharma manufacturing solutions company absolutely committed to delivering exceptional solutions to the global pharmaceutical industry. The company’s diverse product range of Capsules, Films & Foils, Engineering, and Inspection systems meets international regulatory requirements. ACG is committed to just one goal: to offer everything needed for efficient capsule and tablet manufacturing.

ACG has over 5 decades of experience and is present in over 100 countries, with more than 4,500 associates around the world. Our customer-centric approach has won us many loyal, satisfied customers and partners by nurturing relationships.

Image