In a major stride toward next-generation pharmaceutical production, Syntegon has launched its revolutionary SynTiso line concept a state-of-the-art solution designed to redefine how liquid pharmaceuticals are filled. Introduced at Pharmatag 2025 in Crailsheim, the SynTiso system represents a paradigm shift in aseptic processing, promising unprecedented speed, safety, and automation in a highly regulated industry.

Jointly engineered with pharmaceutical industry partners, SynTiso directly addresses some of the sector’s most pressing challenges: maximizing yield, reducing human intervention, and achieving higher throughput all while maintaining impeccable sterility standards. Capable of processing up to 600 containers per minute, it now stands as the highest-output solution on the market for vials, syringes, and cartridges.

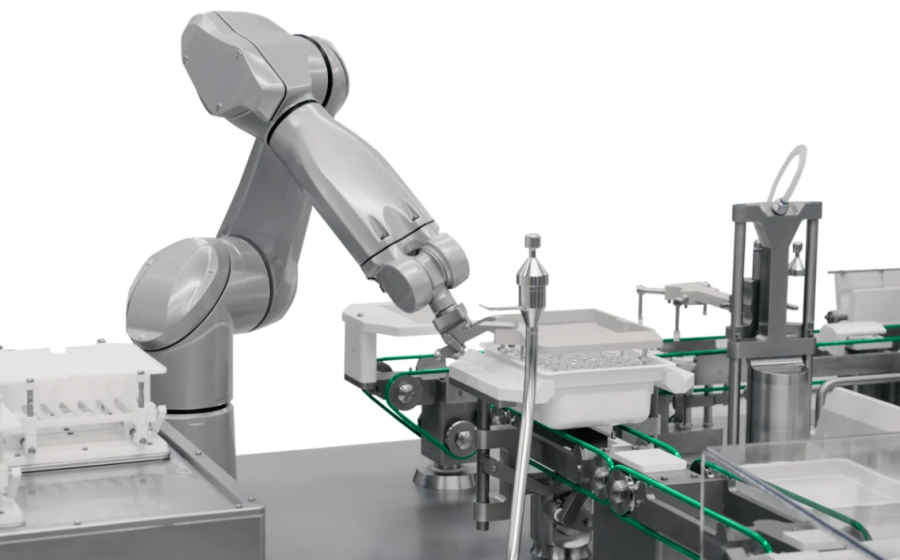

A Gloveless Isolator and Intelligent Automation

At the heart of SynTiso lies a gloveless isolator system, a bold move away from traditional manual interventions. By strategically distancing robotic arms from the critical process zone using them only for essential aseptic tasks SynTiso not only adheres to Annex 1 compliance but also optimizes the First Air principle. This significantly minimizes contamination risk, aided by real-time germ and particle monitoring that eliminates the need for settle plates.

Suspended, Contactless Transport: Clean and Efficient

One of the system’s most innovative features is its contactless, suspended transport system. This advanced design drastically reduces particle generation, eases maintenance, and shortens cleaning cycles particularly beneficial when handling potent compounds like oncology drugs. The streamlined architecture allows for up to 50% faster batch changeovers, saving both time and floor space.

Combined with 100% in-process control (IPC), SynTiso ensures precise, real-time quality assurance with unmatched efficiency. Whether it's large-scale vaccine production or the fast-growing demand for ready to use (RTU) containers, SynTiso is designed to deliver with agility and confidence.

A Collaborative Vision for the Future

“This is more than a machine it’s a co-created platform that embodies our shared vision with customers for the future of aseptic manufacturing,” said Stephan März, Executive VP Pharma Liquid at Syntegon. “SynTiso represents a crucial step toward our goal of a virtually empty isolator: flexible, intelligent, and ultra-efficient.”

With this breakthrough, Syntegon isn’t just responding to the industry’s evolution it’s shaping it.