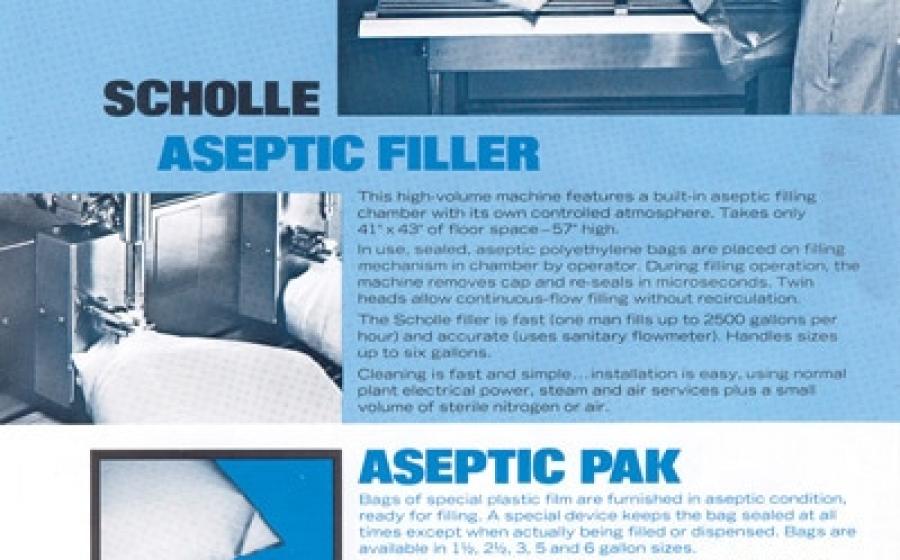

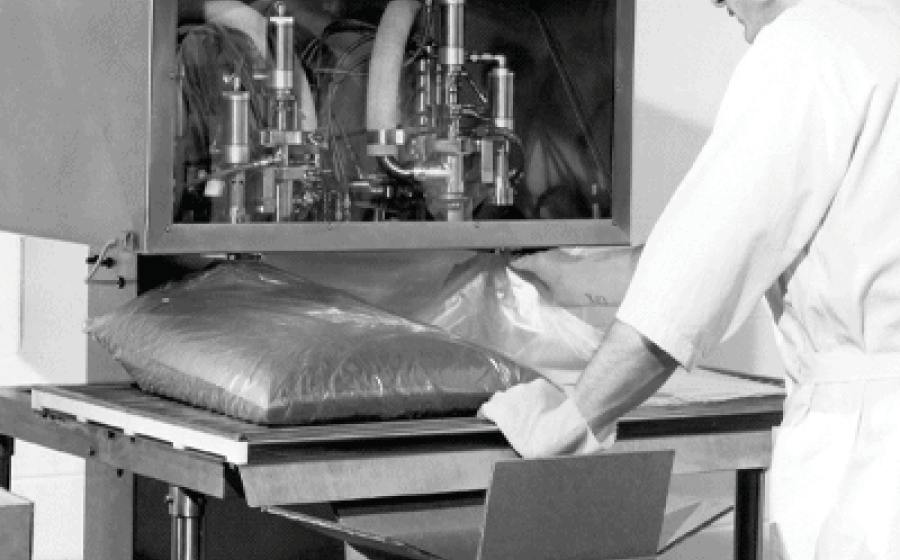

Scholle IPN invented the bag-in-box and revolutionized the way we package goods. Since then, we have continued to find innovative and game-changing ways to utilize packaging technology to transport food safely while reducing our environmental impact.

- Today is: