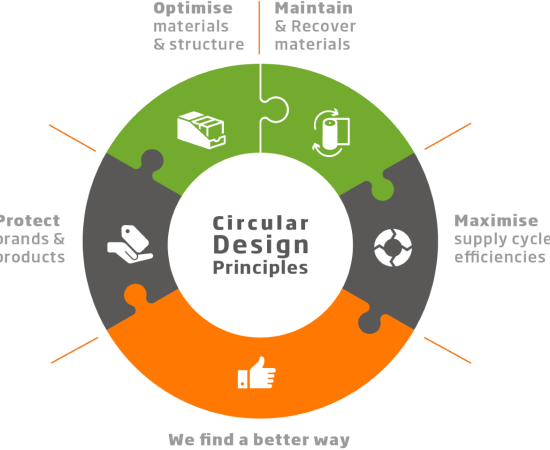

Discover the future of your brand's packaging and production journey

This month Packaging Innovations & Empack opens the doors to the UK’s essential annual event driving business and innovation across the whole packaging journey from primary packaging, secondary packaging, contract packing and fulfilment, labelling and printing and packing and processing technology.