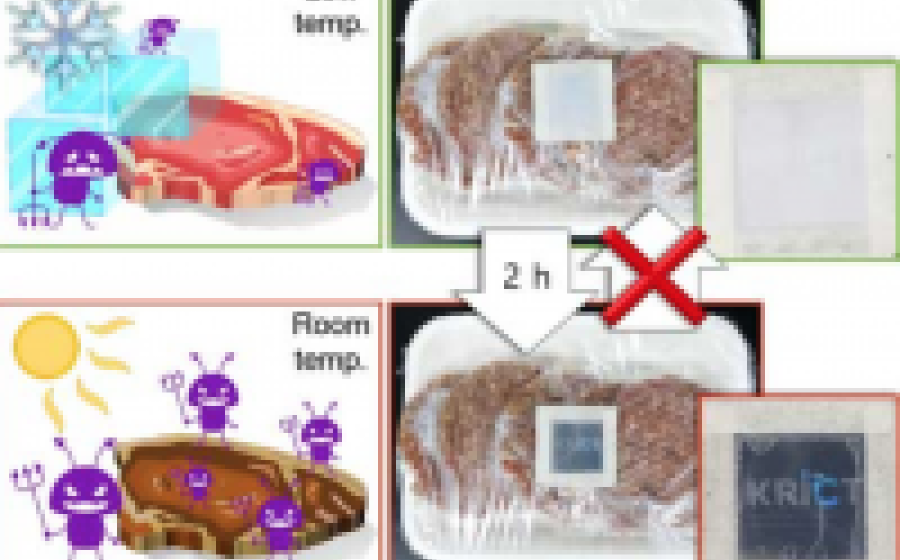

Their research was published in the prestigious journal Advanced Materials IF:25.809 earlier this year: "A Self-Healing Nanofiber-Based Self-Responsive Time-Temperature Indicator for Securing a Cold-Supply Chain." This cold-chain safety sticker creates an image on it when exposed to room temperature (10 0C or higher). Room temperature exposure history and time throughout the cold chain delivery process are indicated but cannot be manually edited. When refrigerated or frozen foods are exposed to room temperature, usually bacteria begin to grow and reproduce. However, it is difficult to see visually as certain bacteria do not affect the taste and smell of foods and frozen foods have almost the same appearance even after melting and refreezing. The core technology of the cold-chain safety sticker is nanofibre film. The researchers attempted to attach a typical film on the back of this newly developed film. At low temperatures, the nanofibre film has a stable structure where thin threads intersect each other, making it opaque because the light is scattered. When exposed to room temperature for a period of time, this structure collapses. Specifically, the thin threads start to melt and become entangled with each other. This allows light to transmit through the film, making it appear transparent. Then the image produced on the typical film on the back becomes visible from the front, showing that the food may have spoiled. The researchers found a way to control the time that is required for the film to become transparent when exposed to room temperature, accounting for variations in spoilage times of different foods. So each sticker was designed to become transparent after a minimum of 30m and a maximum of 24 hours of exposure. This was achieved by controlling the composition and thickness of the nanofibres. Dr Dongyeop Oh from the KRICT said, "This sticker, once exposed to room temperature, cannot be restored to its original state, even if one attempts to refrigerate or freeze it again. Also, room-temperature exposure time cannot be manually adjusted. This means that there is virtually no room for any manipulation." “It does not require modularization, accurately measures localized or gradient heat and functions even after crushing, cutting, and when weight?loaded in a manner that existing TTIs cannot. It also contains no drainable chemicals and is attachable to various shapes because it operates through an intrinsic physical response,” he added. The cold-chain safety sticker can be widely used not only for food product applications but also for the cold-chain distribution of expensive medicine and medical supplies, they say. This is because the sticker is thin and flexible. It is estimated manufacturing cost is low at one cent per unit.