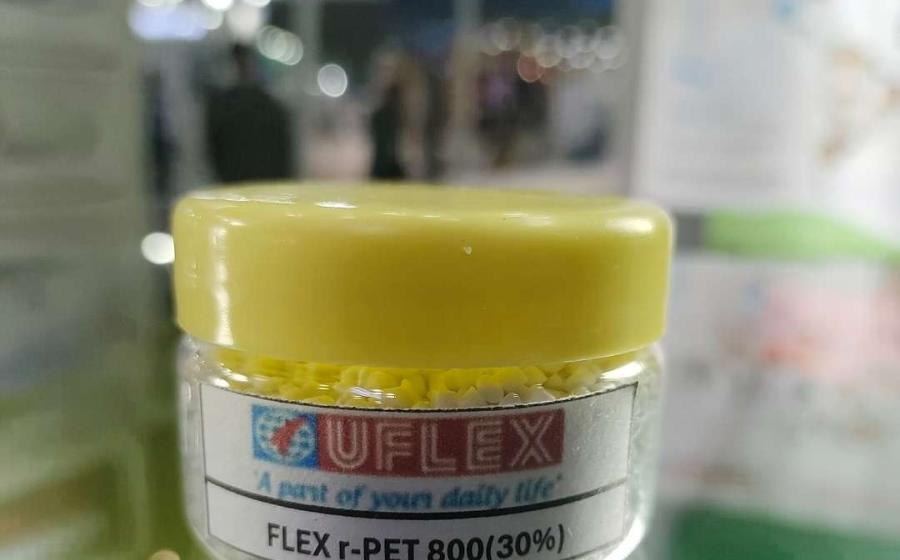

Aligned with the Government of India’s Extended Producer Responsibility (EPR) framework and the latest FSSAI regulations, UFlex’s single-pellet solution offers a seamless option for FMCG brands looking to comply with sustainability targets. Effective April 1, 2025, the new regulations require brands using Category-1 rigid plastic packaging, such as PET bottles, to incorporate a minimum of 30% recycled content by FY26.

- Today is: