With a newly developed tray-loading solution, Qupaq solves urgent challenges regarding flexibility, speed, and capacity among customers in the meat-packing industry. The new Qupaq Flex Loader loads up to 300 products per minute while also providing seamless transitions regarding tray type, and variety and quantity of products.

Qupaq, the company behind the market-leading tray-denesting brands Intray and Anytray, is now expanding its portfolio of tray loaders with a new, innovative solution, the "Qupaq Flex Loader," which combines all features from the previous models regarding adaptability and speed. The solution will be revealed at Anuga Food Tec 2024 in Cologne, Germany, on the 19th of March.

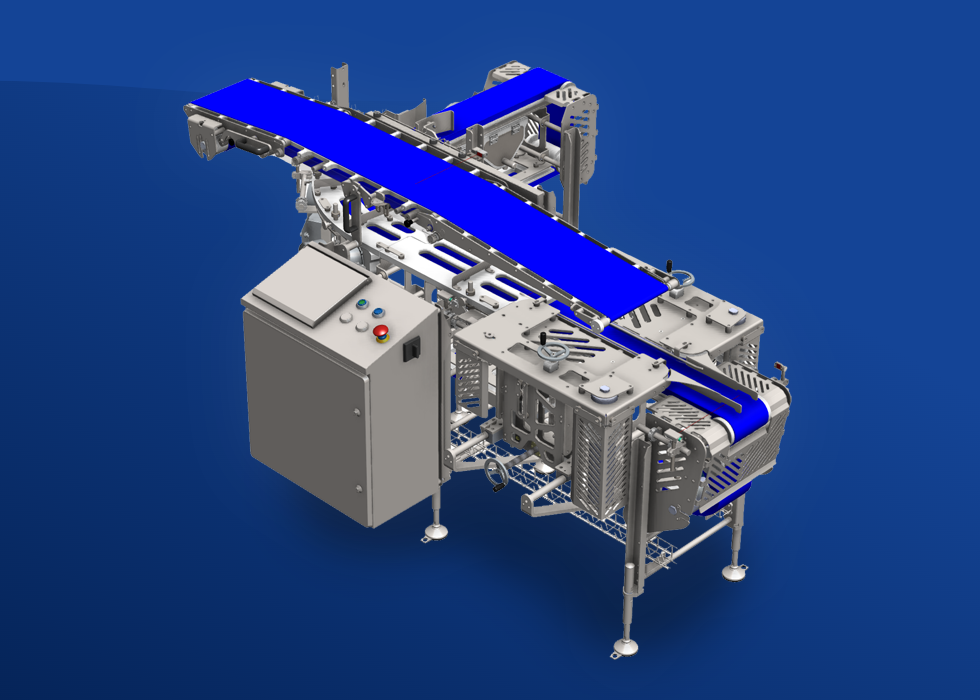

The Qupaq Flex Loader stands out by enabling a combination of high-speed performance and modular flexibility, which allows for immediate adaptation of different trays and product types on the same product line. Among the most important innovations and capacity maximizers are the elimination of space between trays and the tray loading feature generating a vacuum on a perforated belt. As a result, trays will be processed faster and with greater control.

The innovative technology does more than just improve productivity in the meat-packing industry. Additionally, it aligns with the market's transition to more responsive and flexible production methods. The Qupaq Flex Loader demonstrates its versatility by switching between tray types (different sizes, materials, and shapes) and product type (such as minced and sliced meats) in less than a minute, and with no mechanical alternation. Also, a modular design allows a compact inline fit, which is adaptable to any product line setup.

- This is a completely different mechanical concept than we have ever used before. With our Qupaq Flex Loader, you simply adjust the belts in the loading bay rather than changing anything mechanically when you want to switch from one tray type to another, says Carsten Trudslev, Product Manager at Qupaq.

Innovation builds on customer needs and market trends

Capacity is crucial in the meat-packing industry where seasonal variations in meat products call for flexibility and high-capacity processing.

Facing the need to load up to 300 portions of sliced meat per minute, a demand unmet by any exiting tray loader solution available, an international food company reached out to Qupaq for help. This approach has led to the development of what Qupaq itself describes as "the most versatile and adaptable tray loader in the meat-packing industry”.

- Previously in the meat-packing industry, you would typically have one production line dedicated to minced meat, an adjacent line for steaks, and a third line for stacked meat. This layout, however, often led to inefficient utilization due to varying demands for different products resulting in some lines operating at full capacity while the others remained idle. To meet the increasing market demands for more flexible layouts, we wanted to combine multi-product step-loading capabilities with straightforward single-product loading in one single solution. Our Qupaq Flex Loader accommodates this by allowing quick adjustments and combining functionality of multiple lines into one. Meat companies will find it valuable for packing meat products in different patterns in trays, whether in portions, piles, or layers, says Carsten Trudslev, Product Manager at Qupaq.

The design and technology of the Qupaq Flex Loader allows it to work seamlessly with all types of tray-feeding systems on the market, meaning that customers can add it to existing production lines.

The Qupaq Flex Loader is showcased at the upcoming Anuga Food Tec 2024 in Cologne, Germany, 19th to 23rd of March, Hall 6.1, Booth C101, providing an opportunity for industry peers to experience the technology firsthand.

About Qupaq A/S

Qupaq is headquartered in Brønderslev, Denmark, and is the world's leading supplier of tray denesting solutions for the food industry. The company's automatic denesting solutions handle over 10 billion food packaging trays annually in over 50 markets.

Qupaq's product portfolio is comprised of the world's most extensive modular range of denesters, conveyors, and equipment for efficient tray handling and product loading. It includes both the Intray and Anytray denesting brands.

With the rising pressure and costs from inflation and a call for reduced environmental impact, the food industry is looking for valuable tools to accommodate the challenges. Automation stands out as a transformative force, redefining operations, and propelling efficiency. More info at qupaq.com.