Sidel, a leader in innovative PET packaging solutions, is launching its latest quality control technology for PET bottles. IntelliADJUST™ is set to transform customers’ ability to produce PET bottles to a high and consistent standard.

The smart bottle blowing control system offers high performance and easy to use technology that enables customers to achieve a consistently higher bottle quality and support production of bottles with recycled PET (rPET) content.

IntelliADJUST™ is a Sidel patented solution which guarantees consistent quality and high efficiency. It works within a ‘closed loop’ system using interferometric sensor technology, and ensures perfect material distribution, resulting in high production uniformity for PET bottles, including those made from recycled PET.

It also enables consistent bottle quality across a range of variable production conditions, such as preform storage, workshop temperature and relative humidity. In-line, autonomous bottle control and real-time digitised process adjustments result in perfect material distribution. The impact of changing production conditions and PET resin specificities on bottle quality is significantly reduced when using this expert-free solution.

The addition of Sidel’s Evo-ON software suite, offers aggregation of equipment data and dynamic analytics features to deploy historical and 24/7 real-time analysis, creating a truly smart line system.

Stéphane Menard, Product Manager for blowing care at Sidel, explained that IntelliADJUST™ measures in-line bottle thickness, analyses and adjusts parameters to ensure consistent quality:

“This easy-to-use blowing solution, maximises the number of marketable bottles by ensuring that quality control is consistently high. IntelliADJUST™ offsets any production line variations by using algorithms to identify measured thickness deviations and automatically corrects the heating and blowing parameters to ensure consistent quality without any interruptions.”

Moving towards low carbon footprint packaging

The blow moulding process is becoming more important as the drive for ultimate lightweighting and increasing the amount of rPET content within the industry continues.

IntelliADJUST™ is 100% reliable across a wide range of PET preforms including translucent, opaque, coloured (non-TiO2), virgin and up to 100% rPET. It is particularly valuable in helping customers who want to introduce rPET as there are multiple sources of supply and therefore more variability in material grades. The system is capable of securing perfect material distribution on the bottle despite resin variability risks.

Sidel’s new technology offers its customers the opportunity to fully optimise the carbon footprint of their PET packaging, not only through enabling greater use of recycled material but by supporting weight reduction - all with stabilised quality across bottles.

A smart sensor technology for precise measurements and refined production process

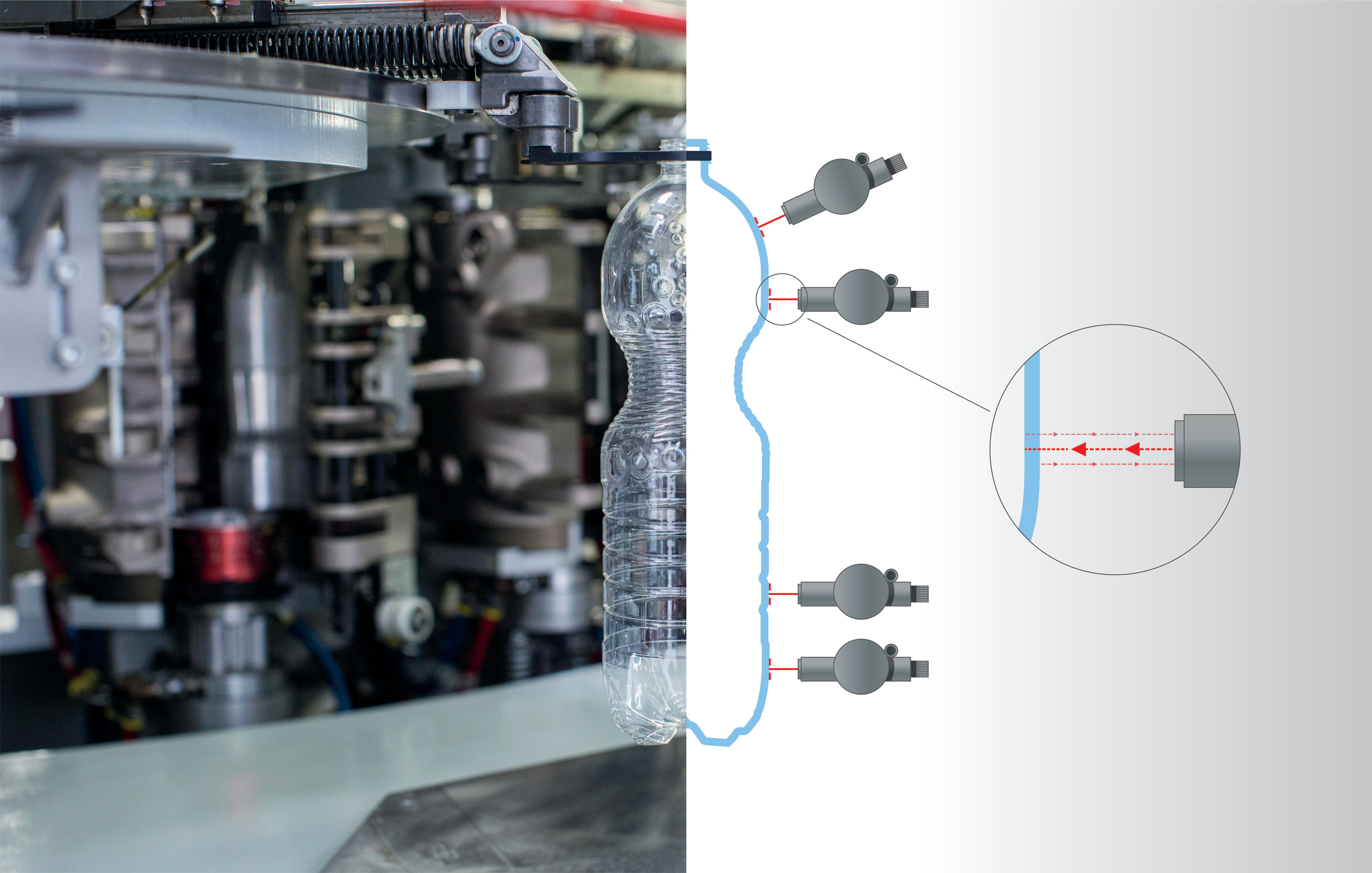

IntelliADJUST™ regulates the main blowing and heating process parameters to avoid uneven distribution of material, while its advanced measurement functionality also ensures consistently high bottle quality.

Sidel applies years of PET packaging expertise to this production process; understanding the relevant points of control on the bottle and which to measure to secure the best material distribution possible.

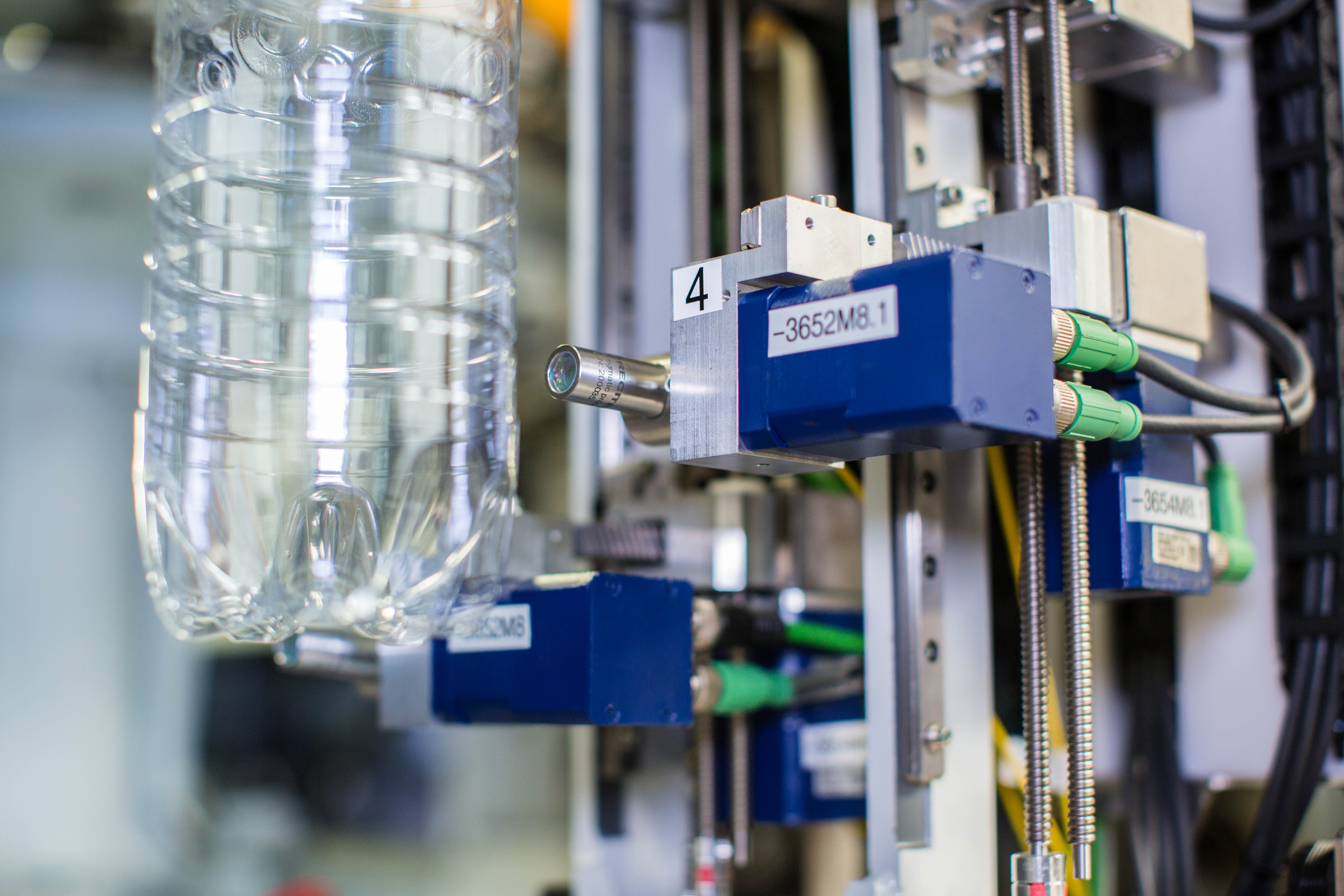

Working within a continuous closed loop process for control and adjustment, IntelliADJUST™ takes high-precision wall thickness measurements at the most representative points of each bottle, using four interferometric sensors based on reflected infrared light. Four sensors, located at the bottle transfer wheel, can be adjusted across three axes (X, Y, and Z).

It can operate at speeds of up to 90,000 bottles per hour, continuously comparing thickness measurements with the expected material distribution, and automatically adjust the process in case of deviation.

The ultimate in-line bottle quality control supporting easy to use and expert-free equipment

With advanced capabilities, IntelliADJUST™ is also easy-to-use and reliable. All IntelliADJUST™ parameters are directly integrated into the machine settings for each stock keeping unit (SKU) recipe. So, this calibration-free system allows immediate start-up after changeovers by automatically adapting sensor positioning and processes according to each recipe. Its high accuracy reduces the need for additional manual laboratory controls.