Düsseldorf (Germany), February 20, 2018 – The technology group GEA will exhibit its wide range of high-tech equipment and possibilities for customized solutions in the area food and drink processing and packaging at FoodEX 2018 in Birmingham from April 16-18.

“FoodEx is a great platform to showcase the breath of expertise GEA has in the food sector. From food and ingredients processing through marination, tenderizing, separation, homogenization to slicing, packaging and refrigeration, we have a large portfolio to share with our customers. So it was quite a natural progression to our theme of the Techonology Supermarket, simply because our customers can pick and choose from a range of standardized equipment or work with us to customize and create complete line solutions for their food or beverage plant.” said Derek Paterson, GEA Head of Food Processing & Packaging Sales in United Kingdom.

When visitors arrive on the GEA stand they can experience the technology through the products they use such as cheese, meat, poultry and beverages, like a real supermarket, and with a series of interactive elements designed to help them see what GEA has to offer in equipment and solutions including technical expertise, complemented by project management, planning and cost control services to achieve flexible and cost-effective food production. Tailor-made service addressing the customers’ needs help to maintain and even improve the performance of technology in the long run. With several options out of the service concept GEA supports customers throughout the entire life cycle of their installed systems and components – from project engineering, installation, and commissioning to production.

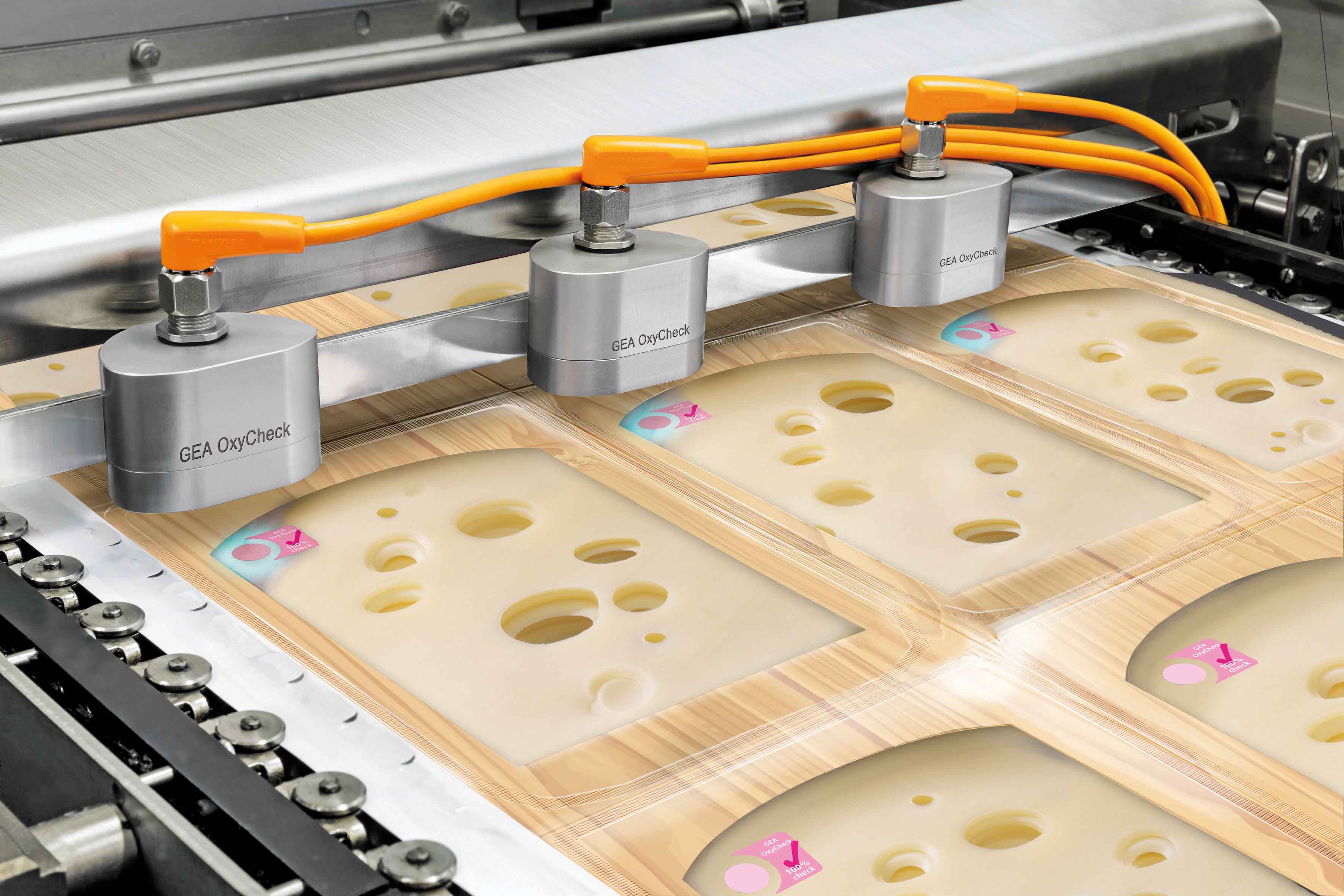

Situated right at the front entrance of Hall 3 the GEA stand V250 will present the GEA DualSlicer, GEA PowerPak – thermoforming machine for packaging with new OxyCheck technology and the GEA SmartPacker CX400, the vertical form-, fill- and seal solution and the GEA Grasso V series, one of the most efficient reciprocating compressors on the market, with electronically controlled service intervals (extended as well as flexible) in order to reduce the Total Cost of Ownership without jeopardizing reliability. With its extensive expertise in cooling systems for industrial and commercial applications including the food, beverage and dairy processing GEA’s emphasis is on the use of reliable, energy-efficient design, natural refrigerants and innovative energy-reuse systems.

A new age for MAP packaging technology

GEA PowerPak is a highly configurable and capable packaging machine for production lines with a high throughput or frequently changing products. Now available with OxyCheck, a unique in-line system for monitoring the quality of remaining oxygen content and the integrity of MAP packaging (Modified Atmosphere Package). The system uses a unique sensor spot printed on the inner side of the top film. The thermoformer-mounted optical sensors project light on the sensor spot and measure the wavelength of the light that fluoresces from the dye. GEA invented a methodology of translating the dye’s fluorescence to O2 content depending on the temperature. The innovation is in the technology accurately measuring the O2 content and seal integrity of every single MAP that exits the thermoformer, without destroying in by a needle as has been done in the past. Costly and wasteful sample testing, previously used on only one percent of the packaging, can be improved and food producers can now check 100 percent of the packs on each line. As a non-invasive quality control system, the film and seal remain intact and neither product nor film material are wasted. Now only checked packages enter the supply chain, GEA can prevent from potential costly recalls for whole batches.