One of the beauties of a new facility is that everything has a fresh start with less chance of breaking for many years. That does not, however, mean the facility should not take precautions against corrosion. In fact, protecting electricals and electronics from corrosion can be one of the first steps toward ensuring a long, healthy service life through good preventative maintenance habits.

High Cost of Corrosion on Electricals and Electronics

Corrosion can cause electricals and electronics to malfunction and fail. The risk is higher in a hot, humid climate and/or near the high chloride sea spray of the ocean. Often, the corrosiveness of a facility stems from its industrial activities. For example, wastewater treatment, pulp and paper manufacturing, and chemical processing create highly corrosive industrial environments. Possible results of accelerated corrosion in these facilities include electrical shorts, frequent repairs, or early replacements of expensive equipment. The potential cost of these damages comes into perspective when considering the experience of one wastewater treatment facility that faced the replacement of $15,000-$40,000 HMI panels once or twice every six months due to the corrosiveness of their wastewater pumping stations. Replacement costs aside, the cost of downtime itself can be substantial due to lost production.

The Ease of Corrosion Protection

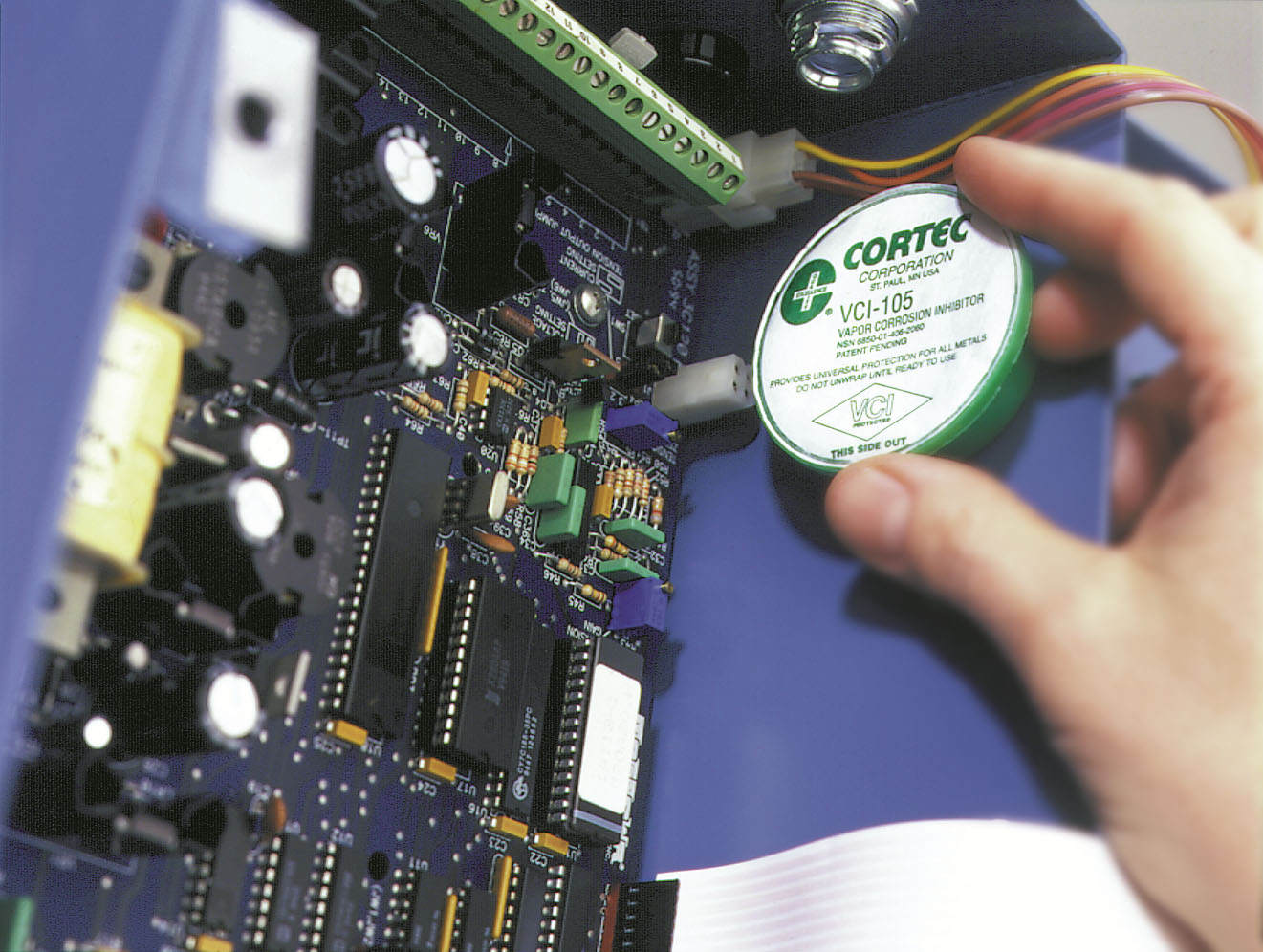

Up against these potentially high corrosion costs is the relatively simple, cost-effective possibility of corrosion protection. Foremost is the use of VpCI® Emitters, small devices that contain Vapor phase Corrosion Inhibitors. Like the workings of a diffuser or air freshener, these devices release vapors that fill the enclosed space. These corrosion inhibiting vapors are attracted to exposed metal surfaces, where they adsorb, forming a protective molecular layer that discourages the corrosion reaction in the presence of oxygen and moisture. If the door of the electrical cabinet is briefly opened, the Vapor phase Corrosion Inhibiting layer will replenish itself once the cabinet is closed again. VpCI® Emitters typically offer enough corrosion protection for at least two years in a fully enclosed space. For additional protection in enclosures that are vented (and thereby lose some of their corrosion inhibiting vapors over time), a light coating of ElectriCorr™ VpCI®-238 can be sprayed on metal contacts and wires inside the panel. In environments such as wastewater treatment facilities with a high amount of H2S, maintenance can add further protection by placing a Corrosorber® cup inside the compartment to absorb the corrosive gases.

Forming Good Preventative Maintenance Habits

Cortec® recommends installing and replacing VpCI® Emitters inside electrical compartments once every two years. Starting this practice at the beginning of a plant’s life forms a protective habit that minimizes the hassle of corrosion damage and failure on electronics and electricals over the years. Application is as simple as calculating the size of the compartment and placing the proper size of VpCI® Emitter inside (e.g., VpCI®-105 Emitter protects 5 ft³ [0.14 m³] of space; VpCI®-111 Emitter protects 11 ft³ [0.31 m³] of space). The sticker on the convenient self-adhesive Emitter cup backing can be placed next to the Emitter to serve as a reminder label of when the VpCI® Emitter was installed and when it needs to be replaced.

Start with Corrosion Protection

Even new plants can be at risk for corrosion when they begin operations or while they await commissioning. Equipping facilities with VpCI® protection from the start can help electricals and electronics run longer without interruptions and costly corrosion-related replacements, making VpCI® Emitters an important part of a good facility preventative maintenance plan. Contact Cortec® to discuss the level of corrosiveness expected and the degree of corrosion preventative maintenance that is appropriate for your facility.