• Fully recyclable mono-material structures significantly more economical

• No compromises when it comes to optical and mechanical properties

• Excellent performance in the converting and printing process

• Printing specialist BOBST displays 18-micron film at drupa 2024

Reifenhäuser Blown Film has produced the world's first MDO-PE film just 18 micrometers thick which meets or exceeds all previous market standards in terms of mechanical properties, appearance, and further processing. The film has been produced on Reifenhäuser EVO blown film lines using the patented EVO Ultra Stretch MDO technology and has been developed and tested for practical suitability in collaboration with raw material manufacturer LG Chem and printing specialist BOBST. The new 18-micron film reduces the amount of material used by around 25 percent compared to previous film thicknesses of 25 microns. This makes the production of fully recyclable mono-material structures significantly more economical.

Christoph Lettowsky, Senior Product Manager at Reifenhäuser Blown Film, explains: "Machine builders and manufacturers have been pursuing the same goal for some time: not to use more material in fully recyclable All-PE solutions than in conventional PET-PE laminates. Technically, this is achieved due to the different densities of PET film and MDO-PE film by replacing the 12 µm PET film with a 16 to 17 µm MDO-PE film. With the reduction to 18 µm, we have taken a significant step in this direction - with further downgauging potential for the future."

High process stability thanks to EVO Ultra Stretch

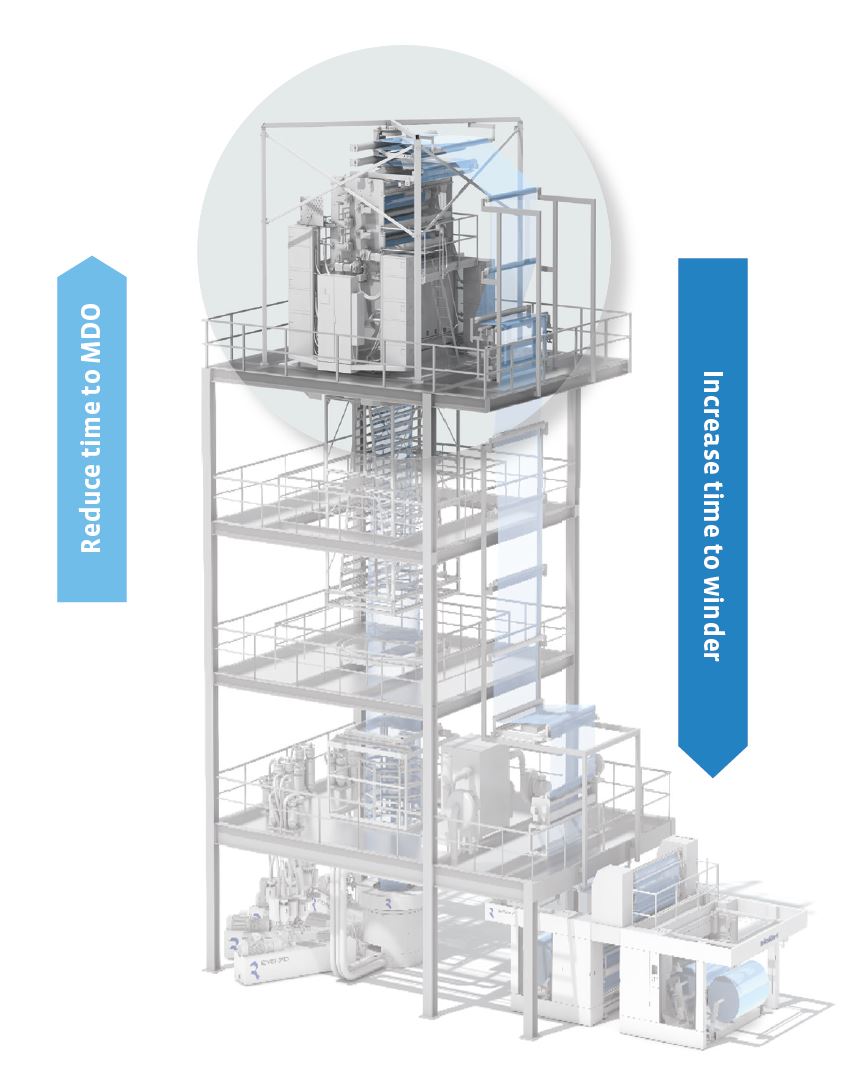

This leap in development was made possible by the combination of MDO Ultra Stretch technology with suitable raw materials. Thanks to the patented position of the Ultra Stretch unit directly in the system's haul-off, the film is stretched from the first heat. This makes the process particularly reliable: Reifenhäuser has produced the 18-micron MDO-PE film stably and reproducibly over many hours in the test runs.

Mechanical and optical properties reach or exceed market standard

Despite the low film thickness, producers do not have to make any compromises when it comes to optical and mechanical properties. With a modulus of elasticity MD exceeding 1,400 MPa and a modulus of elasticity TD exceeding 1,100 MPa, the 18-micron MDO-PE film achieves the current market standard for stretched PE films. With a haze of less than 5 percent, the 18-micron MDO-PE film performs even better in terms of optical properties than the market standard, which is 6 to 7 percent.

Print results impress BOBST

The 18-micron MDO-PE film also performed excellently in the converting process and exceeded all expectations of printing specialist BOBST. Davide Rossello, Head of Competence Center and Process Manager Gravure at BOBST says: "The way this extra-thin 18-micron MDO-PE blown film behaves on our printing machines is unique on the market. We have printed the film at high speeds of up to 500 m/min with excellent results in terms of printing quality and register performances. But even more impressively, we were able to demonstrate the quality of our machine when printing in the BOBST oneECG process, achieving excellent print results at 300 m/min (and above)."

Samples will be exhibited at drupa 2024 in Dusseldorf (Germany)

Printed samples of the new 18-micron MDO-PE film will be on display at drupa 2024 from May 28 to June 7 at the BOBST stand B30-1 in hall 10. Mohamed Timol, expert for MDO processes and applications, will be present at the stand as Reifenhäuser's contact person. Interested parties are cordially invited to see the quality of the film for themselves

The development project from the partners LG Chem, BOBST and Reifenhäuser shows what is possible when outstanding machines, processes and materials come together. The result is an MDO-PE film which, thanks to downgauging, lowers the manufacturing costs of fully recyclable packaging, reduces its product carbon footprint, and enables more sustainable further processing thanks to its outstanding product properties.

About the Reifenhäuser Group

The Reifenhäuser Group together with its highly specialized business units is the leading provider of innovative technologies and components for plastics extrusion. Founded in 1911, the company is a global supplier of high-tech solutions. With its technologies and the know-how of its 1,750 employees, Reifenhäuser has the world's largest network of expertise in plastics extrusion technologies. The CEO of the Group is Bernd Reifenhäuser.