Solvay, a global market leader in specialty materials, has introduced Diofan® Ultra736, a new polyvinylidene chloride (PVDC) coating solution with ultra-high water vapor barrier that allows carbon footprint reduction for pharmaceutical blister films. As an aqueous dispersion, Diofan® Ultra736 meets regulatory requirements for direct pharmaceutical contact and supports the design of sustainable films with thinner coating designs.

“Consumers and legislators are requesting increased efforts related to carbon footprint reduction from the packaging industry, and one of the most effective means to this end is to reduce the size and weight of packaging products,” says Federico Baruffi, Global Marketing Manager, Packaging, Solvay Specialty Polymers. “Our new Diofan® Ultra736 coating solution can help packaging film manufacturers achieve superior barrier properties with thinner structures, leading to a significant carbon footprint reduction of the blister film.”

Diofan® PVDC coatings are widely used in pharmaceutical blister packaging to protect sensitive solid-dose drug preparations as well as in the packaging of delicate food and similar other consumer goods. They can be applied on both plastic and paper-based substrates and are often preferred for their unique combination of water vapor and oxygen barrier.

Diofan® Ultra736 PVDC coating was custom-engineered to maximize the water vapor barrier without sacrificing its high oxygen barrier, chemical resistance or transparency. The product also exhibits excellent thermoformability, enabling smaller pack sizes with higher pill density if compared with incumbent alternative coating solutions.

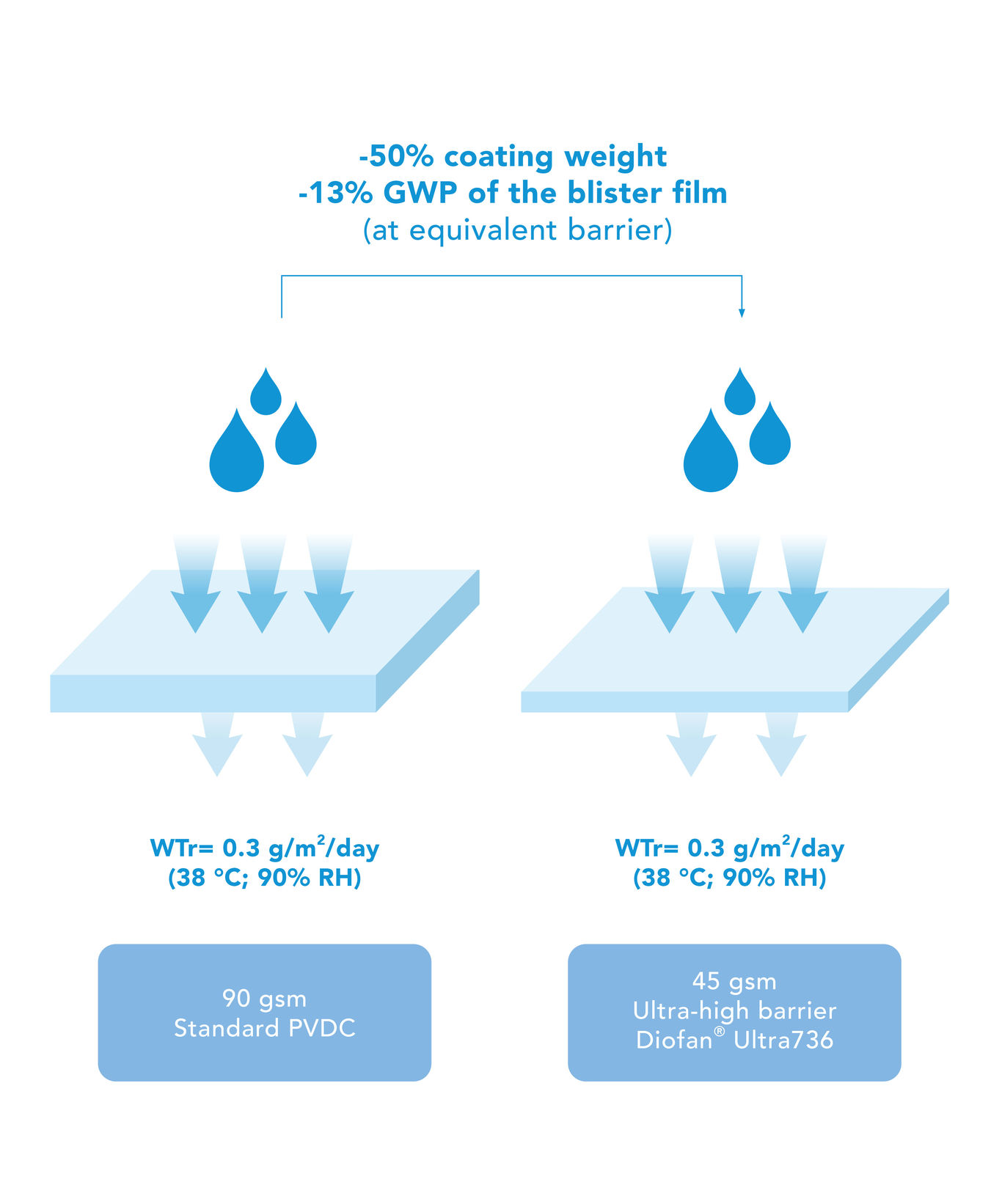

Thanks to its ultra-high barrier performance, Diofan® Ultra736 allows the reduction of the coating thickness compared to incumbent mid to high barrier PVDC coatings, without impacting the functionality. In particular, it has been shown that, for Duplex barrier structures, Diofan® Ultra736 enables halving the number of base coat layers while delivering the same water vapor barrier. This approach can contribute to decreasing the overall carbon footprint of final blister film structures by up to 13%.

With regulatory compliance for pharmaceutical-contact applications, Diofan® Ultra736 PVDC is globally available for sampling.