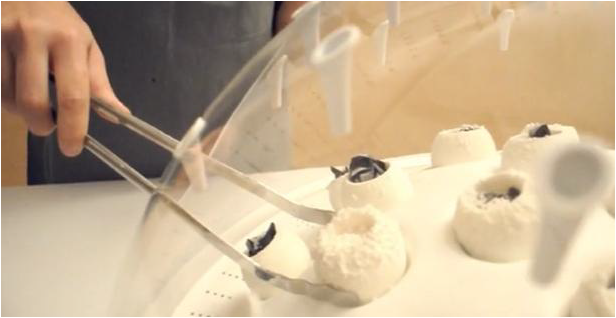

Unger, a Austrian designer partnered with Julia Kaisinger and Utrecht University to develop a system prototype known as Fungi Mutariu. Fungi Mutarium is so intriguing that it not only uses nature to process synthetic waste to break down plastic and grow edible, fluffy biomass. The idea came from a 2012 study by researchers at Yale University, who found a rare mushroom in the Amazon called Pestalotiopsis microspora that was capable of breaking down polyurethane - the main ingredient used in plastics. Not only could this fungus live entirely off polyurethane, it could do so in an anaerobic (oxygen-free) environment that resembles the bottom of a landfill. As it turns out, species of plastic-eating fungus are actually pretty common, and together with fellow designer Julia Kaisinger and scientists from Utrecht University, Unger identified two that would be perfect for their device: Pleurotus ostreatus - aka the oyster mushroom - and Schizophyllum commune, a species that's listed as inedible in the UK and US, but is popular in parts of Mexico and India. These two fungi used come from the mycelium (roots) of oyster mushrooms and split gill mushrooms are most popular mushrooms in the world. Working: The device features a series of little white cups that are made from agar (seaweed-derived gelatin), starch, and sugar, and thin slices of plastic waste that have been previously sterilised with UV light are placed inside. The mycelium (or roots) of P. ostreatus and S. commune mushrooms are dropped into the cups, and as they grow, they feed off the plastic waste and nutrients in the cup walls. The pods are placed in the “growth sphere”, a dome-like incubator. Next, liquified fungi sprouts are dribbled into the agar pods. After few weeks, edible fungi begin to grow. After several months, the fungi will completely decompose the plastic, into a natural, edible growth so the agar cup filled with edible fluffy white mycelium." Once the plastic has fully degraded, the harvested pods can be eaten whole and have a mild taste. While eating mushrooms that have been processing plastic waste for the past few weeks doesn't sound all that appetising or safe, the fact that the mushrooms aren't all that interested in retaining the toxic components of the plastic means they don't accumulate it in their cells, so, in theory, they're safe for us to eat.