MADERA, CA, April 15, 2020 — JBT Corporation (NYSE: JBT), a leading technology solutions provider to the global food and beverage industry, has introduced a new breakthrough for Continuous Rotary Sterilizers called Gentle Can Handling (GCH) which reduces damage to food containers as they run through the sterilization process. GCH has the potential to enable customers to achieve higher speeds and more throughput or run lighter weight cans which may provide significant cost savings.

For over 100 years, food processors have utilized the Rotary Pressure Sterilizer (RPS) to agitate and sterilize food products in hermetically sealed metal cans. However, over time, in the relentless effort to reduce cost and increase efficiency, processors have requested higher speeds from JBT and lighter weight cans from their suppliers.

The early days of 25 cans per minute has evolved into speeds in excess of 1000 cans per minute for the modern RPS, but a combination of the higher speeds, lighter weight cans and new can geometries has, at times, resulted in unacceptable damage to cans. However, that has all changed thanks to a global team, consisting of JBT engineers from South Africa, Belgium and the US, who collaborated to design a new technology called Gentle Can Handling. This technology can be applied to both new RPS equipment and retrofitted to existing RPS equipment.

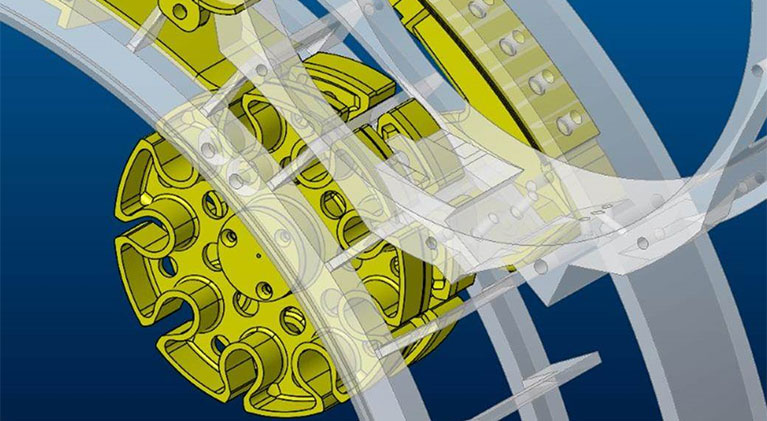

Andrew Prins, JBT Technical Product Manager for Retort & Rotary, said: “After a can is filled and seamed, that sealed container goes into a rotary cooker in a continuous manner, entering the pressure cooker through a valve that works like a revolving hotel door on its side, and exiting in the same manner as a sterile product. But when you make contact with the can with the ejector that pushes it out of the reel and into the valve, you may cause damage to the container. We have come up with a new shape for the ejector and modified the other transfer components so that the can is removed from the reel and enters the valve in a more stable and controlled manner which reduces the impact forces the can experiences and thus can damage is greatly reduced.”

GCH, continued Prins, allows for much greater control the whole way through the process, so there is a gentler movement of the containers from one shell to the next. And because it is much smoother, it can also potentially run faster. With a maximum speed of about 600 cans a minute per lane, JBT customers are able to process up to 1200 cans a minute over two lanes.

“Gentle Can Handling provides processors with an improved technology to reduce can damage and potentially use lighter weight cans that may provide significant cost savings.” Prins added.

About JBT

JBT Corporation (NYSE: JBT) is a leading global technology solutions provider to high-value segments of the food & beverage industry with focus on proteins, liquid foods and automated system solutions. JBT designs, produces and services sophisticated products and systems for multi-national and regional customers through its FoodTech segment. JBT also sells critical equipment and services to domestic and international air transportation customers through its AeroTech segment. JBT Corporation employs approximately 6,500 people worldwide and operates sales, service, manufacturing and sourcing operations in more than 25 countries.