In previous blogs, we detailed adhesives in terms of their classification and application. In this piece, we will talk about different chemical compositions and structures. So, let’s begin!

Adhesives can either be natural or synthetic based on their source. Natural adhesives include animal, plant and mineral-derived adhesives. Albumin, casein, dextrin, soybean protein, starch, amber and paraffin are a few components that comprise of category that is natural sources of adhesive materials.

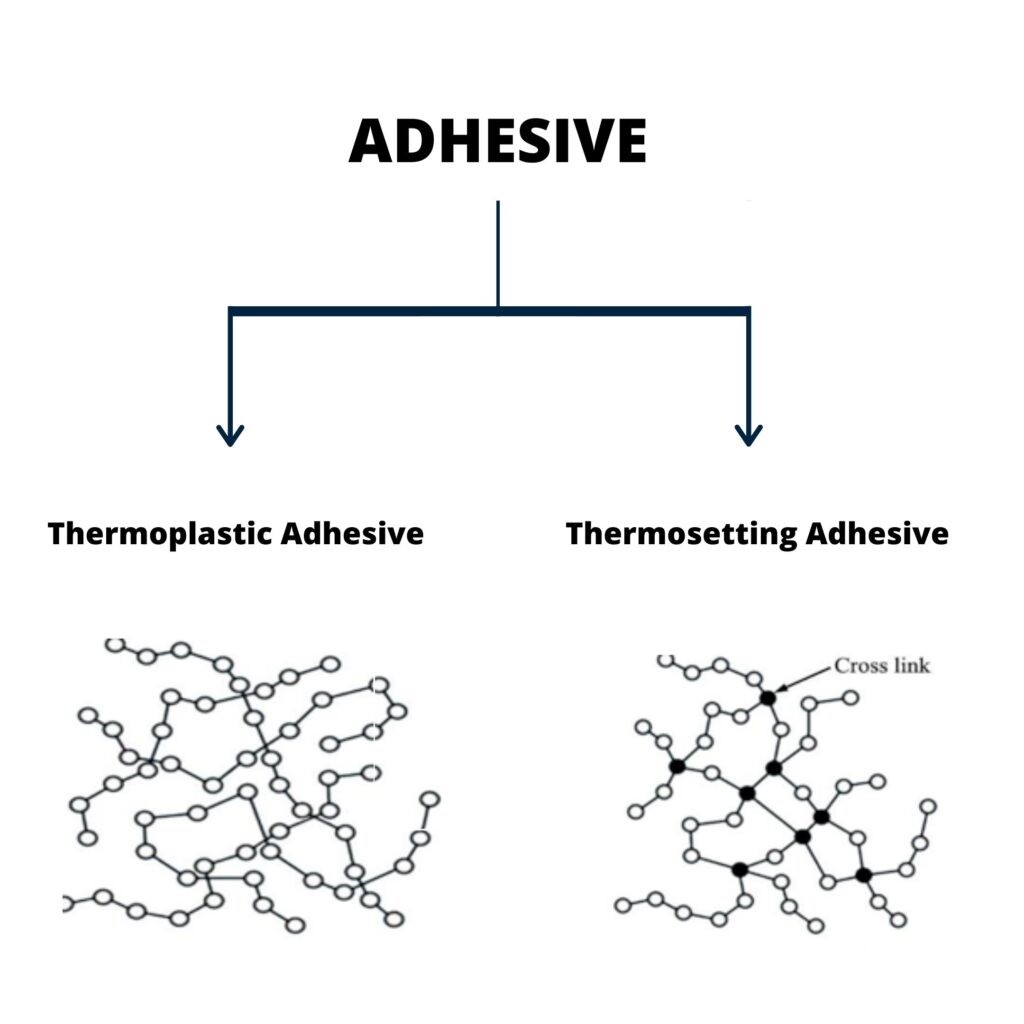

Synthetic adhesives are developed using human-made polymers and are more prevalent in the industry today. Industrial applications require stronger bond strength and durability that this category of adhesives is able to provide. Synthetic adhesives can be further classified into thermoplastic, thermosetting and elastomeric adhesive. These constitute of adhesives derived from acrylic, polyurethane, polyamide, silicone and many other types of polymers.

• Thermoplastic Adhesives: They have no curing period and either cool or dry upon application. Cellulose derivatives, polyacrylates, polyethers, polysulfones, saturated polyesters, and vinyl polymers and copolymers can all act as a base for thermoplastic adhesives.

• Thermosetting Adhesives: They are cured to undergo permanent and irreversible chemical crosslinking. Heat, pressure, exposure to moisture, radiation and employing a catalyst are all curing methods depending upon the type of thermosetting adhesive used. Amino plastics, epoxies, furanes, phenolic resins, polyaromatics, and unsaturated polyesters are all used in thermosetting adhesives.

• Elastomeric Adhesive: Also recognized as rubber adhesives, they are elastic, durable, and capable of withstanding extension and compression stresses. A curing period may or may not be required depending on the type of rubber adhesive.

1. EPOXY ADHESIVES: These thermosetting adhesives are temperature and solvent resistant and can be structurally bonded to metals, ceramics, wood and plastic.

2. POLYURETHANE ADHESIVES: There are both thermoplastic and thermosetting varieties of this adhesive. They tend to provide high bond strength and elasticity. They require moisture to set.

3. POLYIMIDE ADHESIVES: Known for their strength, and chemical and heat resistance, their formulation can either be thermoplastic or thermosetting.

4. POLYAMIDE ADHESIVES: Polyamide adhesives can also be thermosetting or thermoplastic