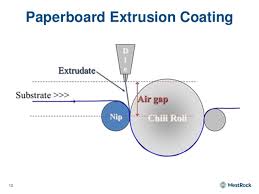

Paperboard is coated with plastics to combine the mechanical properties of the paperboard with the barrier and sealing properties of plastics. Paperboard combined with a relatively small number of plastic materials will provide the extra features needed to make the paperboard suitable for a number of specially demanding applications. Extrusion coating is a process whereby molten plastic is applied to paperboard and subsequently chilled to form an extremely thin, smooth layer of uniform thickness.

The molten plastic can be used as an adhesive to laminate a plastic film or a metal foil. Extrusion coating and lamination are used to achieve:

- moisture protection

- barrier to water vapour, oxygen, aroma, etc.

- grease resistance

- heat sealability

- sales appeal, for example shiny surfaces.

Sales appeal: The use of extrusion coated and laminated paperboard provides outstanding promotional benefits in terms of visual appeal and consumer handling. High gloss is created by extrusion coating and a specific high gloss chill roll. A metallic effect is created by lamination with aluminium foil or metallised polyester film. These materials and processes also provide tactile sensations of high quality and luxury which the consumer associates with high value products packaged in these materials.

Examples of extruded and laminated products providing sales appeal

- PE (polyethylene) extrusion coating of paperboard with a gloss or matt finish. Printing and gluing (with cold glue) can be done on a corona-treated surface.

- PP (polypropylene) and PET (polyethylene terephthalate) are two heat resistant polymers that, applied on the board, can be used in oven applications.

- Aluminium foil and metallised polyester film may be laminated to the paperboard to provide a metallic effect. Printing can be done on a pre-treated surface.

Functional coating: Paperboard as such is suitable for the packaging of dry products in general.

However, plain paperboard is only suitable for direct contact with moist and greasy foods to a limited extent, because moisture will affect the mechanical properties of the paperboard, and absorbed grease will cause stains. Such effects will obviously reduce the protective function of the package and may detract from the appearance as well. Extrusion coating or lamination adds a thin layer of plastic to the paperboard. Plastic coatings can provide resistance to grease and moisture and, where appropriate, be heat resistant. Plastic coatings can be heat sealed and in some constructions these seals can be leak proof. Depending on the application, the paperboard may be extrusion coated on one or two sides. Aluminium lamination provides packages with a barrier to light, moisture, grease and gases. The aluminium foil is often plastic coated to provide product safety and heat sealing abilities.

Key characteristics: A number of process parameters influence the grammage of the coating.

The most important are:

- flow of the plastic melt

- temperature of the plastic melt.

Source of the above information: https://www.iggesund.com/globalassets/iggesund-documents/rm-pdfer/1.-fr…