Adhesives and peel

Adhesive and Peel Technology: Crash Course Part 2

Following the previous blog which discussed the forces affecting the nature of an adhesive, this piece will focus on the two types of peels; Adhesive Peel and Cohesive Peel.

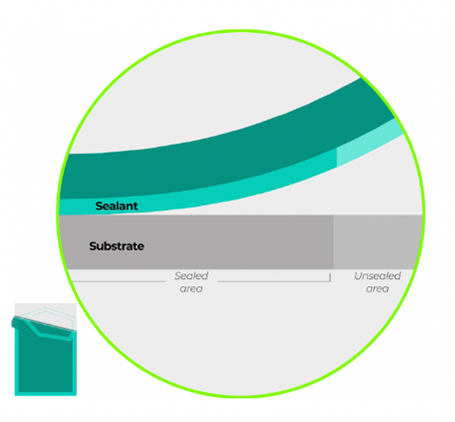

Typically, an adhesive peel leaves both joined surfaces intact after peeling. This means no residual adhesive resides on either of the surfaces post-peel. This peel technology is the market trend and how you would observe most adhesives to work.

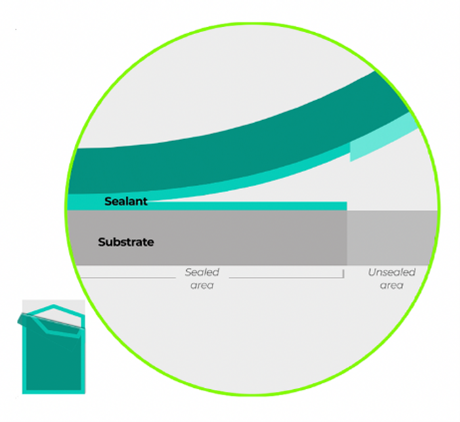

In a cohesive peel sealant, when pulled apart, the sealant layer splits in half. Each half sticks to the surface attached to it.

The difference in composition between an adhesive peel sealant and a cohesive peel sealant is that an adhesive peel sealant is composed of a singular polymer while a cohesive peel sealant contains an additional, incompatible polymer to disrupt the matrix. It is the weakening of the uniform polymer matrix that creates the cohesive nature of the adhesive.

Cohesive peel technology is advantageous in controlling the variability in peel strength, reducing fiber tear, and offering a consistent peel for the user.

Colored cohesive peels are useful in ensuring seal integrity. They are a visual indicator of whether the package has been opened before or not. Before opening, the user can observe the tinted seal for any non-uniformities.

With cohesive peel, seal strength can also be altered by choosing different secondary polymers to disrupt the matrix. Greater disparities between the viscosities of the primary and secondary polymer increase the seal strength.

Cohesive peel sealants also have a consistent seal strength over a wider range of activation temperatures. This means that, unlike adhesive peel sealants, they are less reliant on seal temperature or dwell time for a certain seal strength.

Seeing the benefits of this emerging technology, we might soon see a change in market trends.